Filling machines are an essential part of many industries, allowing for efficient and accurate filling of containers with a variety of products. From food and beverage to pharmaceutical and cosmetic industries, filling machines are a critical piece of equipment that helps streamline the manufacturing process.

There are several types of filling machines available in the market, and each one is designed to suit specific needs and products. In this article, we will explore the different types of filling machines, their applications, and their advantages.

1.Gravity Filling Machines

Gravity filling machines use the force of gravity to fill containers with liquid products. The containers are placed below a tank containing the liquid, and the liquid flows through a valve or nozzle into the container. Gravity filling machines are commonly used in the food and beverage industry to fill containers with water, juice, or oil.

The advantage of gravity filling machines is that they are simple to use and require minimal maintenance. They are also cost-effective and can fill containers quickly and efficiently.

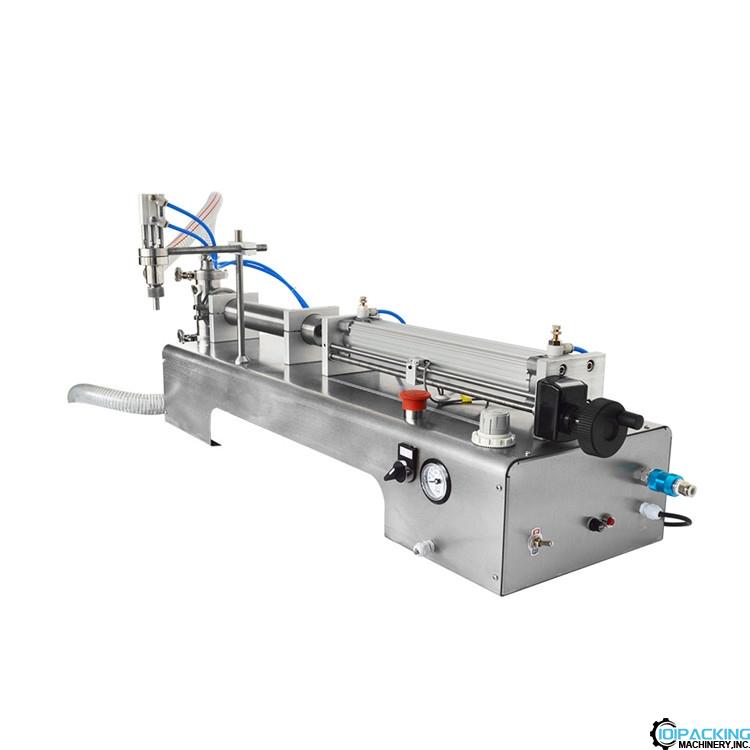

2.Piston Filling Machines

Piston filling machines use a piston to measure and dispense a precise amount of product into containers. The piston moves back and forth within a cylinder, creating a vacuum that draws the product into the cylinder. The piston then pushes the product out of the cylinder and into the container.

Piston filling machines are commonly used for thicker products, such as creams or gels, and are also suitable for filling containers with a variety of sizes and shapes. The advantage of piston filling machines is their accuracy and consistency, ensuring that each container is filled with the exact amount of product.

3.Overflow Filling Machines

Overflow filling machines fill containers to a specific level by using a nozzle that fills the container to the brim and then recirculates the excess back into the holding tank. Overflow filling machines are commonly used in the food and beverage industry for filling containers with products such as sauces or dressings.

The advantage of overflow filling machines is their precision, ensuring that each container is filled to the same level, regardless of variations in the container's shape or size.

4.Vacuum Filling Machines

Vacuum filling machines use a vacuum to fill containers with liquid products. The container is placed below the filling nozzle, and the vacuum created within the container draws the product into the container. Vacuum filling machines are commonly used for filling containers with foaming products, such as shampoos or soaps.

The advantage of vacuum filling machines is that they can fill containers with high levels of precision, ensuring that each container is filled with the exact amount of product. They are also suitable for filling containers with products that are difficult to handle or have unique properties.

5.Auger Filling Machines

Auger filling machines use an auger to measure and dispense a precise amount of powdered or granulated products, such as spices or coffee. The auger rotates within a cylinder, moving the product towards the filling nozzle. The product is then dispensed into the container.

The advantage of auger filling machines is their accuracy and consistency, ensuring that each container is filled with the exact amount of product. They are also suitable for filling containers with a variety of sizes and shapes.

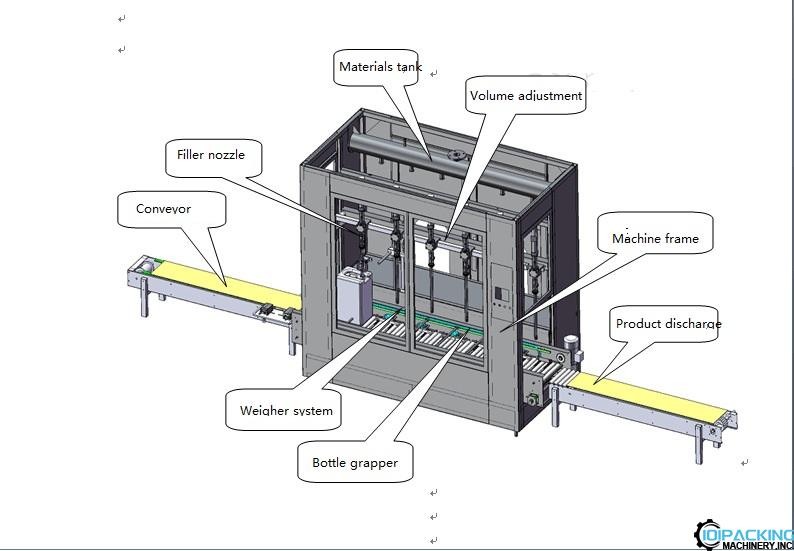

6.Net Weight Filling Machines

Net weight filling machines weigh the product as it is dispensed into containers, ensuring that each container is filled with the correct amount of product. The container is placed on a scale, and the product is dispensed until the desired weight is reached.

The advantage of net weight filling machines is their precision, ensuring that each container is filled with the exact amount of product. They are also suitable for filling containers with products that have unique properties, such as products that are viscous or have a high level of foam.

7.Volumetric Filling Machines

Volumetric filling machines use a volume-based measurement system to dispense a precise amount of product into containers. The product is measured as it flows through a chamber or tube, and the volume is controlled by adjusting the speed of the filling pump. Volumetric filling machines are commonly used in the pharmaceutical and cosmetic industries for filling containers with liquid products.

8.Aseptic Filling Machines

Aseptic Filling Machines: These machines are used for filling sterile products, such as medical fluids and food and beverage products that require a long shelf life. They use aseptic processing to prevent contamination during filling..

The advantage of volumetric filling machines is their accuracy and consistency, ensuring that each container is filled with the exact amount of product. They are also suitable for filling containers with a variety of sizes and shapes.

In conclusion, filling machines play a critical role in many industries, allowing for efficient and accurate filling of containers with a variety of products. From gravity filling machines to volumetric filling machines, each type of machine has its unique advantages and applications. When choosing a filling machine, it is important to consider the product being filled, the container size and shape, and the desired level of precision. By selecting the appropriate filling machine, manufacturers can increase efficiency, reduce waste, and improve the overall quality of their products.

Contact: 101Packing

Phone: +86 198 7511 8892

E-mail: info@101packing.com

Add: 5th Floor, Outside Building, Shangxue Tech Park, Jihua Road, Longgang District, Shenzhen,Guangdong,China