In today's fast-paced world, efficient and precise packaging is crucial for businesses to meet the demands of consumers and maintain a competitive edge. The Box 3D Film Wrapping Packaging Machine has emerged as an innovative solution, transforming the packaging process and delivering superior results in terms of efficiency, productivity, and product protection. This article will explore the key features, benefits, and applications of the Box 3D Film Wrapping Packaging Machine, highlighting how it is revolutionizing the industry.

What is box 3D film wrapping packaging machine?

The Box 3D Film Wrapping Packaging Machine is a type of packaging equipment that is specifically designed for wrapping or packaging various products using a 3D film. It is a versatile machine that can handle different types of packaging materials, such as OPP or BOPP films, to securely wrap and seal boxes or products.

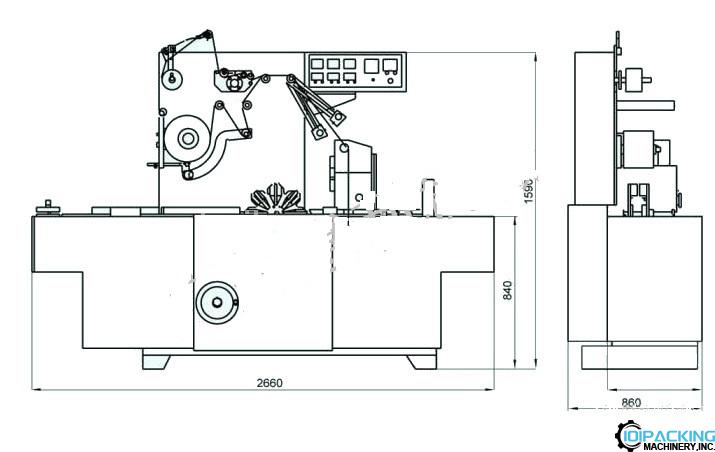

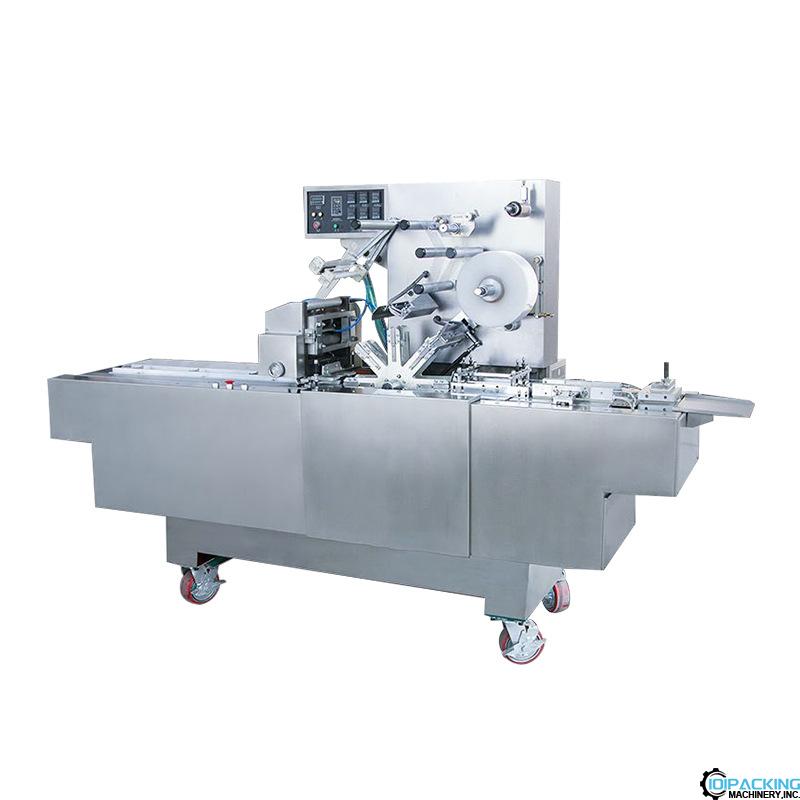

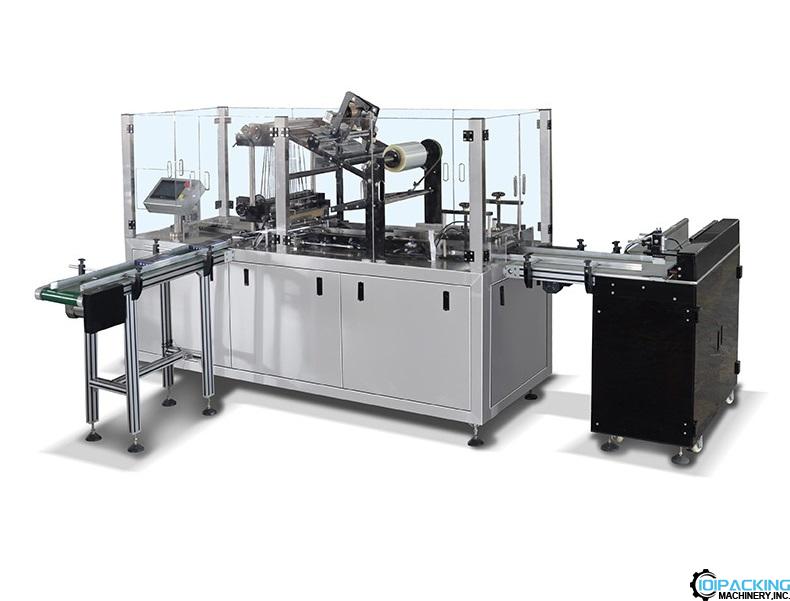

This machine is equipped with advanced features and mechanisms to automate the packaging process, improving efficiency and productivity. It typically consists of a conveyor system that transports the box or product through the packaging area, where the 3D film is wrapped tightly around it. The film is then sealed to create a secure and tamper-evident packaging. The machine may also include additional features like tear tape applicators for easy opening, adjustable settings for different box sizes, and controls for temperature, speed, and tension.

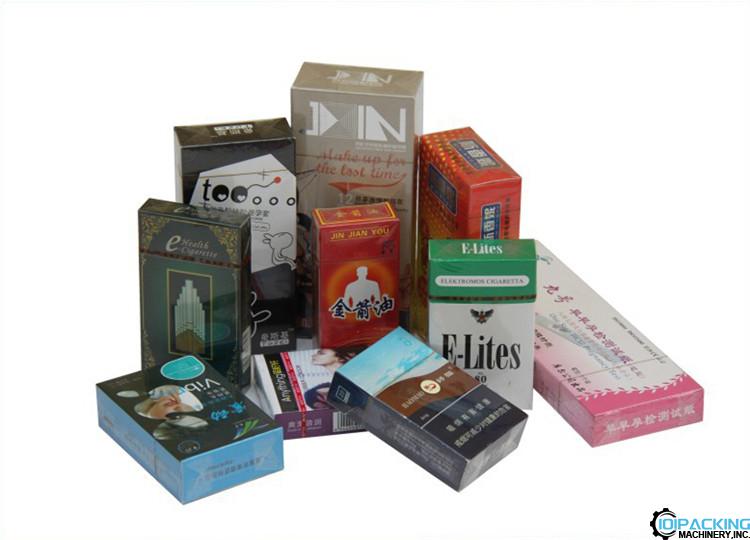

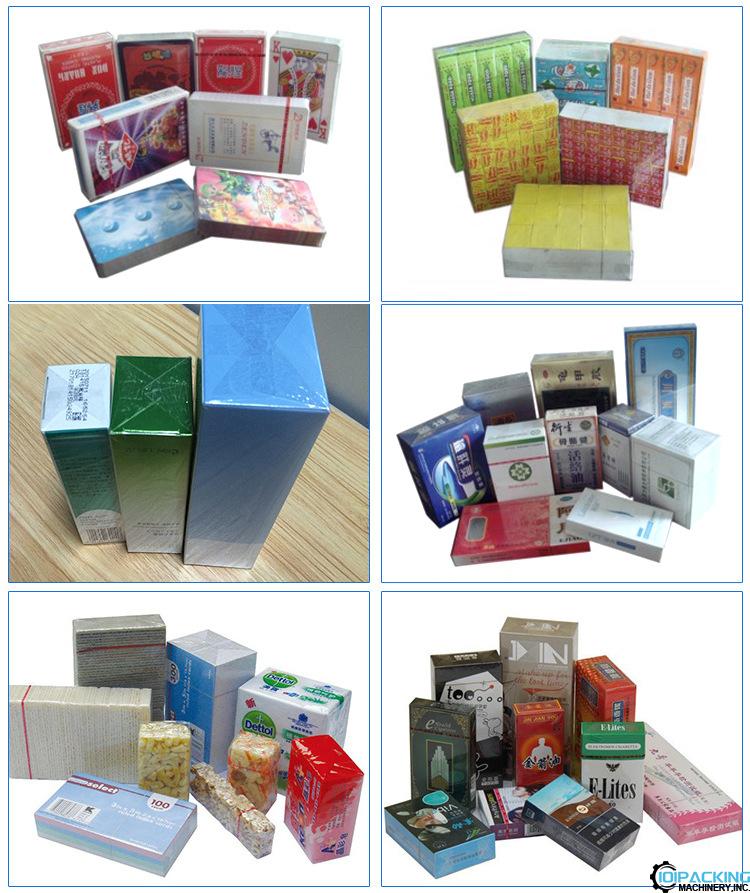

The Box 3D Film Wrapping Packaging Machine is commonly used in various industries, including food and beverage, cosmetics, pharmaceuticals, and electronics. It offers benefits such as improved packaging consistency, enhanced product protection, and increased production efficiency compared to manual wrapping methods.

There are various types of Box 3D Film Wrapping Packaging Machines available in the market, each designed to cater to different packaging needs and requirements. Here are a few common types:

1.Fully Automatic Box 3D Film Wrapping Machine: This type of machine is fully automated, requiring minimal human intervention. It incorporates advanced technology and features like automatic film sealing, cutting, and tension control. These machines are suitable for high-volume production environments.

2.Semi-Automatic Box 3D Film Wrapping Machine: This type of machine combines automatic and manual processes. While some functions such as sealing and cutting may be automated, the loading and feeding of boxes or products may require manual intervention. Semi-automatic machines are often chosen for medium-scale production operations.

3.Compact Tabletop Box 3D Film Wrapping Machine: This type of machine is smaller in size and designed to be placed on a tabletop or workbench. It is suitable for lower volume production or where space is limited.

4.Customizable Box 3D Film Wrapping Machine: Some manufacturers offer customizable machines that can be tailored to specific packaging requirements. These machines can accommodate different box sizes, film materials, and additional features like tear tape applicators or printing capabilities.

It's important to select the appropriate type of Box 3D Film Wrapping Packaging Machine based on factors such as production volume, packaging specifications, and available space in the facility. Consulting with the machine manufacturer or supplier can help determine the most suitable type for specific packaging needs.

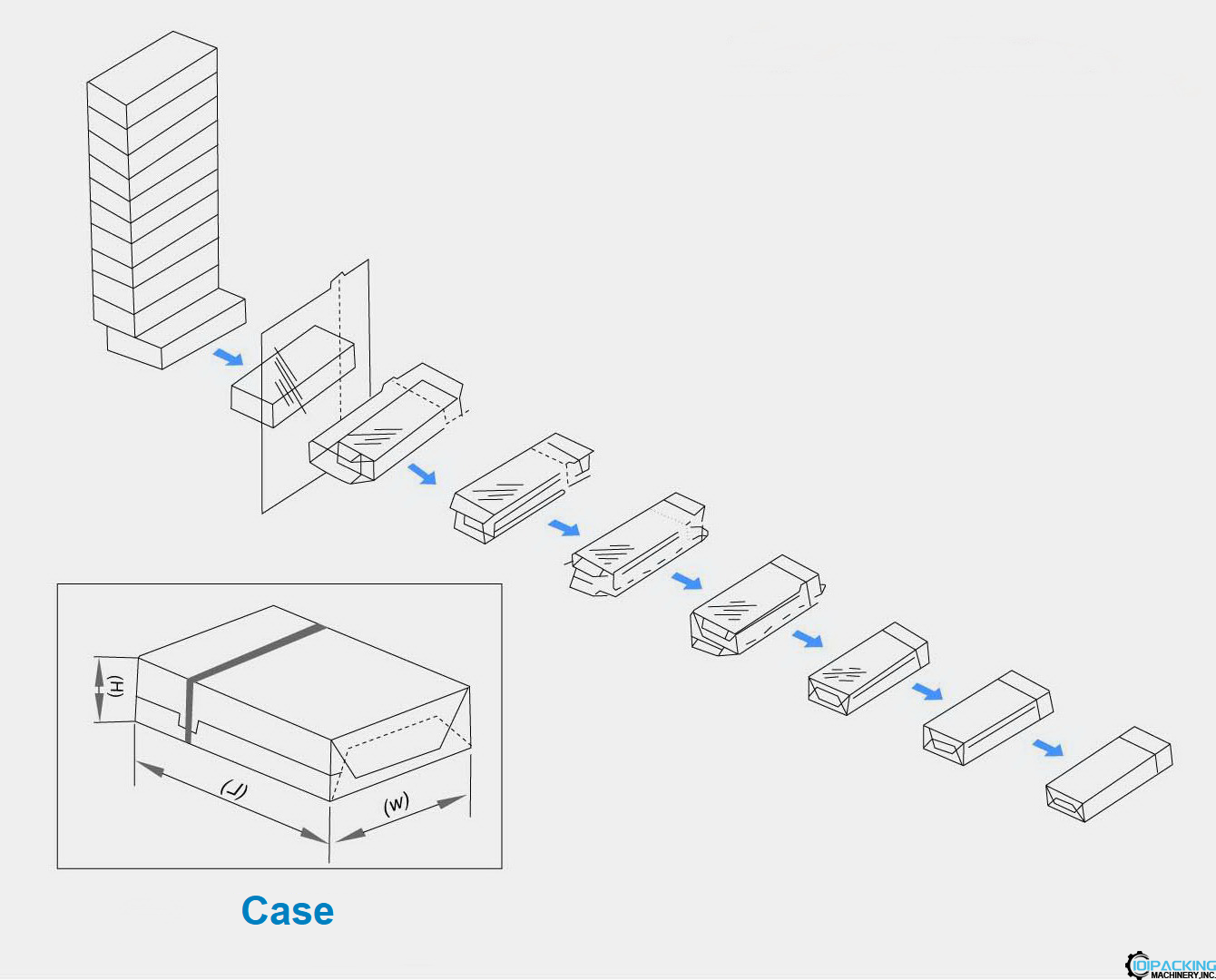

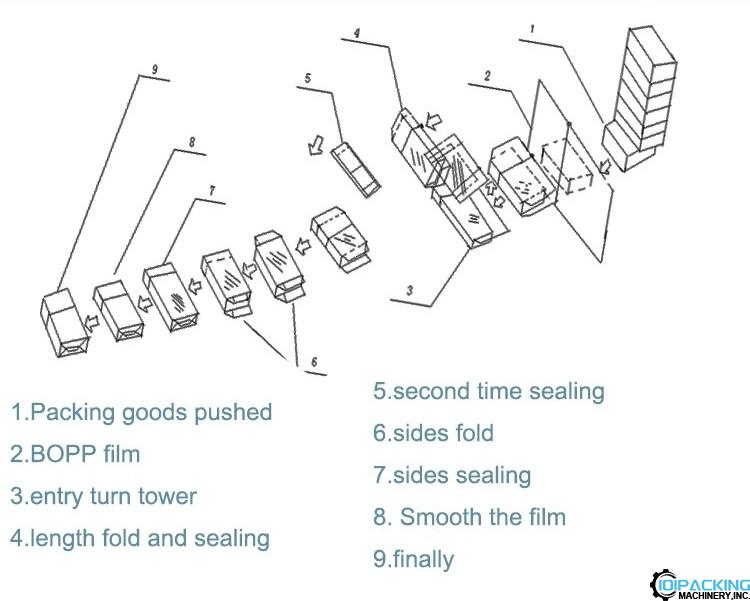

Working Flow of the Box 3D Film Wrapping Packaging Machine:

1.Set Up and Configuration:

The first step in utilizing the Box 3D Film Wrapping Packaging Machine is the initial setup and configuration. Operators will need to ensure that the machine is placed in the appropriate location within the packaging facility and properly connected to the power source. They will also need to configure the machine's settings, such as temperature, speed, and tension, according to the specific packaging requirements.

2.Loading and Positioning:

Once the machine is set up, the next step is to load the boxes or products onto the conveyor system. The operator will position each item correctly to ensure that it passes through the packaging zone smoothly and reliably. The machine's conveyor system can be adjusted to accommodate different box sizes and product shapes, ensuring flexibility in packaging operations.

3.Film Placement and Wrapping:

With the products in position, the Box 3D Film Wrapping Packaging Machine will then initiate the wrapping process. The machine pulls the film from the roll and positions it correctly around the product. It utilizes 3D film technology, ensuring that the film wraps tightly around the box or product, providing a secure seal and protection against dust, moisture, and tampering. The tension and speed of the film can be adjusted to ensure optimal wrapping results.

4.Heat Sealing and Cutting:

As the film is wrapped around the product, the Box 3D Film Wrapping Packaging Machine employs heat sealing technology to create a secure bond. The heated elements within the machine generate the necessary temperature to melt the film and fuse it together, creating a tight seal. Once the seal is complete, the machine will then cut the film precisely, ensuring a clean finish that is ready for storage or distribution.

5.Tear Tape Application (Optional):

Some models of the Box 3D Film Wrapping Packaging Machine are equipped with tear tape applicators. In such cases, the tear tape is automatically applied to the film during the wrapping process. The tear tape provides a convenient opening mechanism for end consumers, allowing them to easily open the packaging without the need for additional tools.

The working flow of the Box 3D Film Wrapping Packaging Machine involves a series of steps that streamline the packaging process and deliver superior results. From initial setup and configuration to the final output of securely wrapped products, the machine's automated processes, versatility, and precise wrapping capabilities revolutionize the packaging industry. By adopting this advanced packaging solution, businesses can significantly improve efficiency, productivity, and product protection, ultimately enhancing customer satisfaction and gaining a competitive advantage in their respective markets.

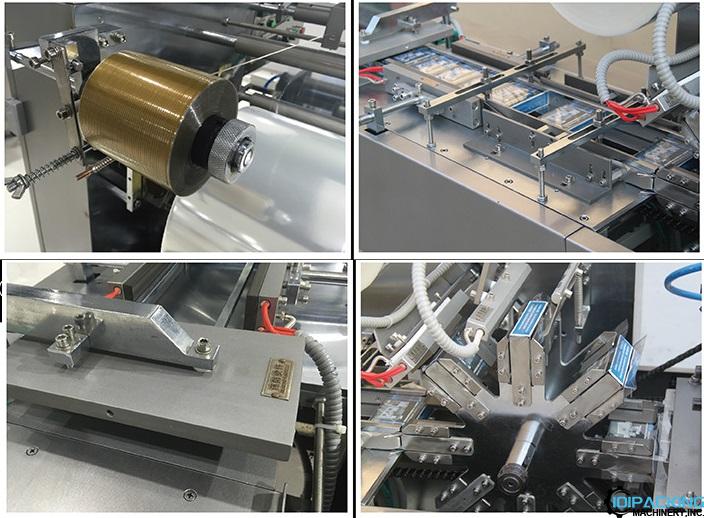

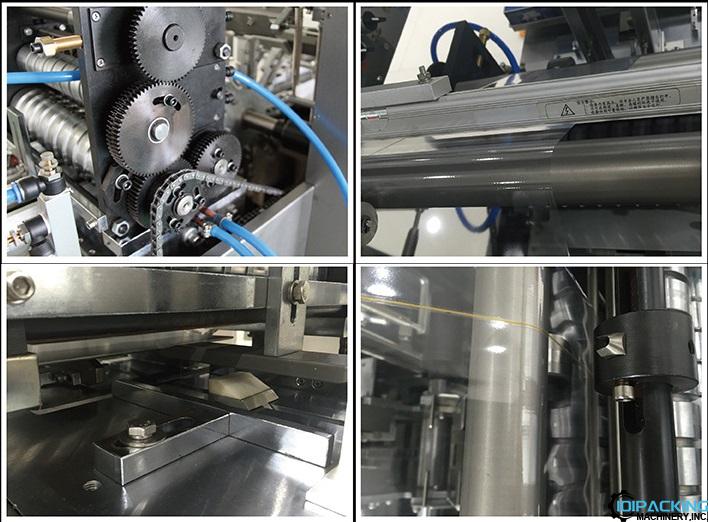

The working principle of the Box 3D Film Wrapping Packaging Machine is based on the integration of various mechanisms and technologies to automate the process of wrapping boxes or products with film.

1.Conveyor System: The machine is equipped with a conveyor system that moves the boxes or products through the packaging zone. The conveyor system can be adjusted to accommodate different box sizes and product shapes, ensuring smooth and consistent movement.

2.Film Roll and Dispensing Mechanism: The machine is equipped with a film roll holder and dispensing mechanism. The film roll is placed on the machine, and the dispensing mechanism feeds the film onto the product surface.

3.ilm Wrapping Mechanism: The film wrapping mechanism is responsible for initiating the wrapping process. It pulls the film from the roll and positions it correctly around the box or product. The mechanism ensures that the film wraps tightly around the item, providing a secure seal and protection.

4.Heat Sealing Mechanism: Once the film is in position, the machine utilizes a heat sealing mechanism to create a secure bond. This mechanism consists of heated elements that generate the necessary temperature to melt the film and fuse it together. The heat sealing process creates a tight seal around the box or product.

5.Cutting Mechanism: After the heat sealing process, the machine incorporates a cutting mechanism to trim the film precisely. The cutting mechanism ensures a clean finish, with no excess film, ready for storage, transportation, or display.

6.Tear Tape Applicator (Optional): Some models of the Box 3D Film Wrapping Packaging Machine are equipped with tear tape applicators. The tear tape is automatically applied to the film during the wrapping process, providing a convenient opening mechanism for end consumers.

7.Control System: The machine's control system allows operators to configure various settings, such as temperature, speed, tension, and film length. This control system ensures optimal wrapping results, customization to specific packaging requirements, and consistent performance.

What is OPP and BOPP packaging film?

OPP (Oriented Polypropylene) and BOPP (Biaxially Oriented Polypropylene) are types of packaging films commonly used in the packaging industry. Here's a brief explanation of each:

1.OPP Film: OPP stands for Oriented Polypropylene. It is a versatile and widely used packaging film that is made from polypropylene materials. OPP film is known for its transparency, excellent tensile strength, and moisture-resistant properties. It provides good protection against moisture, dust, and scratches, making it suitable for a range of packaging applications. OPP film is commonly used for wrapping various products like food items, cosmetics, CDs/DVDs, and more.

2.BOPP Film: BOPP stands for Biaxially Oriented Polypropylene. BOPP film is a variant of OPP film that undergoes a biaxial stretching process during manufacturing. This stretching process imparts enhanced mechanical characteristics to the film, including improved clarity, higher tensile strength, and superior stiffness. BOPP film offers excellent barrier properties against moisture, gases, and odors, making it suitable for applications that require high-quality packaging. BOPP film is commonly used for packaging snacks, confectionery, tobacco products, textiles, and more.

Both OPP and BOPP films can be further customized with different surface finishes, such as matte, glossy, or holographic, to enhance their appearance and shelf appeal. They can also be printed with high-quality graphics and logos to create visually appealing packaging designs.

OPP and BOPP films are widely preferred in the packaging industry due to their versatility, durability, cost-effectiveness, and superior packaging properties.

What is the sealing temperature of OPP and BOPP film?

The sealing temperature for OPP (Oriented Polypropylene) and BOPP (Biaxially Oriented Polypropylene) packaging films can vary depending on factors such as film thickness, machine type, and packaging requirements. However, in general, the sealing temperature for OPP and BOPP films typically ranges between 110°C (230°F) to 150°C (302°F).

The sealing temperature is critical to achieving a proper seal when using OPP or BOPP films. If the temperature is too low, the film may not seal properly, resulting in weak seals that can easily open or peel. If the temperature is too high, it can lead to film distortion or even burning, compromising the integrity of the packaging.

To determine the ideal sealing temperature for a specific OPP or BOPP film, it is recommended to conduct trial runs and make adjustments based on the packaging machine and film specifications. Additionally, manufacturers and suppliers of OPP and BOPP films usually provide guidelines regarding the recommended sealing temperatures for their specific products.

It is important to note that the sealing temperature can also be influenced by other factors such as dwell time (the duration for which the heated sealing jaw applies pressure), pressure, and film speed. These parameters can be adjusted as well to optimize the sealing process and ensure a secure and reliable seal for the packaging.

Features of the Box 3D Film Wrapping Packaging Machine:

1.Versatility and Customization:

One of the standout features of the Box 3D Film Wrapping Packaging Machine is its versatility. It can accommodate a wide range of packaging materials such as OPP and BOPP films, allowing businesses to choose the most suitable film for their specific needs. The machine can be easily customized to handle different box sizes and product shapes, providing businesses with flexibility in their packaging operations. Whether it's boxes, pouches, or shrink-wrapped products, the Box 3D Film Wrapping Packaging Machine can handle various packaging applications with precision.

2.Enhanced Product Protection:

Products packaged using the Box 3D Film Wrapping Machine benefit from enhanced protection during storage and transportation. The tightly sealed 3D film provides a barrier against dust, moisture, and tampering, ensuring the integrity of the packaged goods. This level of protection is particularly vital for industries such as food and beverage, pharmaceuticals, and electronics, where product freshness, safety, and security are paramount.

3.Improved Efficiency and Productivity:

By automating the packaging process, the Box 3D Film Wrapping Machine significantly improves efficiency and productivity. Manual packaging tasks, which are time-consuming and prone to human error, are eliminated, allowing workers to focus on other critical aspects of production. The machine's high-speed capabilities and consistent wrapping quality result in faster processing times, enabling businesses to meet tight deadlines and manage higher production volumes.

4.User-Friendly Operation:

The Box 3D Film Wrapping Packaging Machine offers a user-friendly operation that requires minimal training. Its intuitive controls and clearly labeled mechanisms make it easy for operators to set desired parameters such as temperature, speed, and tension. Additionally, many machines incorporate features like tear tape applicators, making it convenient for end consumers to open the packaging without requiring additional tools. This user-friendly design not only improves operational efficiency but also enhances the overall customer experience.

5.Applications in Various Industries:

The Box 3D Film Wrapping Machine finds applications across a wide range of industries. In the food and beverage industry, it is used for packaging items like cereal boxes, snack bars, and beverage cartons. In the cosmetics industry, it protects items such as perfumes, creams, and cosmetics sets. Pharmaceuticals utilize the machine for the packaging of medicines, syringes, and medical devices. Even electronic items like mobile phones, tablets, and accessories can benefit from the precise and secure packaging provided by this machine.

Conclusion:

The Box 3D Film Wrapping Packaging Machine has revolutionized the way products are packaged, offering businesses unparalleled efficiency, precision, and product protection. Its automated processes, versatility, and customizable features make it an indispensable tool for optimizing the packaging process in various industries. By embracing this innovative machine, businesses can streamline their operations, reduce costs, and ultimately enhance customer satisfaction. As the demand for efficient and precise packaging continues to rise, the Box 3D Film Wrapping Packaging Machine stands as a game-changer in the world of packaging.

Contact: 101Packing

Phone: +86 198 7511 8892

E-mail: info@101packing.com

Add: 5th Floor, Outside Building, Shangxue Tech Park, Jihua Road, Longgang District, Shenzhen,Guangdong,China