In recent years, Blow Fill Seal (BFS) machines have become increasingly popular in the pharmaceutical industry for their highly efficient and aseptic manufacturing process. BFS machines are used to produce small-volume parenteral (SVP) liquid dosage forms such as eye drops, nasal drops, and injectable solutions. This article will explore the many advantages of BFS machines and why they have become a game-changer in pharmaceutical production.

The BFS process involves three main steps: molding, filling, and sealing. The molding step involves the creation of a plastic container by extruding molten plastic into a mold. The filling step involves the injection of the drug product into the container, and the sealing step involves closing the container and sealing the opening. This closed system minimizes the risk of contamination, making the BFS process an ideal choice for the production of sterile pharmaceutical products.The BFS process involves three main steps: molding, filling, and sealing.

1.Molding: The first step in the BFS process is molding, which involves the creation of a plastic container by extruding molten plastic into a mold. The mold has two halves that are brought together to form the container. The molten plastic is extruded through an orifice, forming a tube called a parison. The parison is then cut to the desired length and clamped between the mold halves. Compressed air is then blown into the parison, causing it to expand and take the shape of the mold. The mold halves are then separated, and the container is removed.

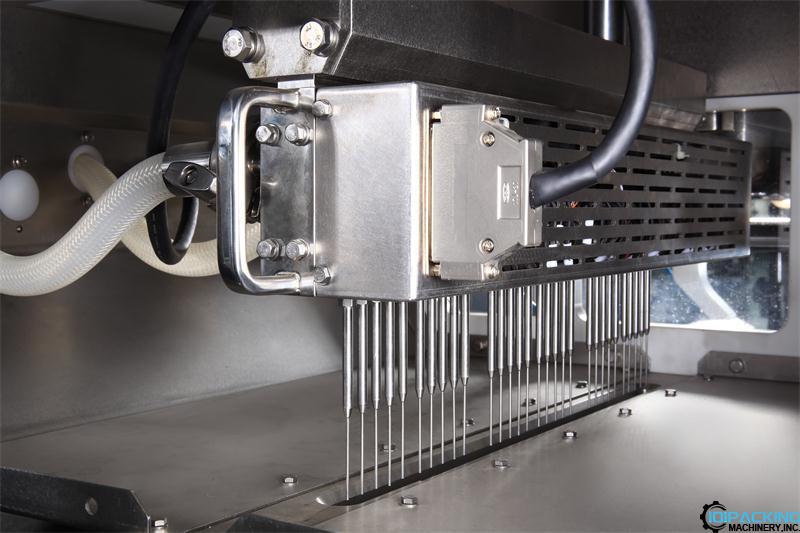

2.Filling: The second step in the BFS process is filling, which involves the injection of the drug product into the container. The filling needle is inserted into the container through a small opening, and the drug product is injected under pressure. The filling needle is then removed, and the container is ready for sealing.

3.Sealing: The final step in the BFS process is sealing, which involves closing the container and sealing the opening. The mold halves are brought together, and the open end of the container is sealed by applying heat and pressure. The sealed container is then removed from the BFS machine and transferred to the packaging station.

The BFS process offers several advantages over traditional manufacturing processes such as glass vial filling. It is a closed system, which minimizes the risk of contamination and eliminates the need for preservatives. The BFS process is also highly efficient, producing up to 600 containers per minute. Finally, the BFS process is highly customizable, allowing for the production of containers in various shapes and sizes.

One of the key advantages of the BFS process is its high efficiency, with machines capable of producing up to 600 containers per minute. This high output rate has made BFS machines an attractive choice for pharmaceutical companies looking to improve their production processes and increase their output. BFS machines are also highly customizable, allowing for the production of containers in various shapes and sizes.

BFS machines are also highly versatile, with applications in various industries, including cosmetics, food and beverage, and veterinary medicine. The machines are capable of producing a wide range of products, from small, single-dose containers to large, multi-dose containers.

The closed system of BFS machines eliminates the need for preservatives, which can be harmful to patients and cause adverse reactions. This makes BFS machines an ideal choice for the production of sterile pharmaceutical products that require a high level of purity and safety.

Additionally, BFS machines are designed for ease of use and maintenance. They are equipped with intuitive controls and simple operating procedures, making them easy to operate for even inexperienced operators. Routine maintenance is straightforward, with regular cleaning and lubrication required to keep the machine running smoothly.

The high efficiency and aseptic nature of BFS machines have made them an essential tool for pharmaceutical companies looking to improve their production processes and increase their output. By eliminating the need for preservatives and minimizing the risk of contamination, BFS machines offer a safer and more efficient method of producing sterile pharmaceutical products.

Moreover, BFS machines are cost-effective, as they can reduce the cost of production and increase profits for pharmaceutical companies. The high output rate of BFS machines allows for large-scale production, which can help to reduce the overall cost of manufacturing.

In conclusion, BFS machines have revolutionized the way SVP liquid dosage forms are produced, offering a highly efficient and aseptic process that minimizes the risk of contamination and eliminates the need for preservatives. With their high output rate, versatility, and ease of use and maintenance, BFS machines have become an indispensable tool for pharmaceutical companies looking to streamline their production processes and improve product quality. As the pharmaceutical industry continues to evolve, BFS machines will undoubtedly play a key role in shaping its future.

Contact: 101Packing

Phone: +86 198 7511 8892

E-mail: info@101packing.com

Add: 5th Floor, Outside Building, Shangxue Tech Park, Jihua Road, Longgang District, Shenzhen,Guangdong,China