Induction sealing machines are a popular choice in the packaging industry, providing a reliable and efficient way to seal containers for a variety of industries. These machines use electromagnetic induction to create a hermetic seal between a foil liner and the opening of a container, providing a secure and airtight seal that helps to preserve the quality and freshness of products.

In this comprehensive guide, we will explore the types of induction sealing machines available, their working process, benefits, and factors to consider when choosing an induction sealing machine for your business.

How Induction Sealing Machines Work

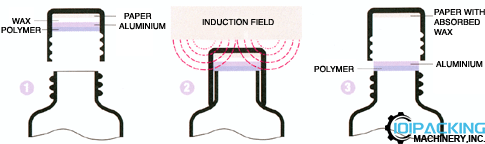

Induction sealing machines use a process known as electromagnetic induction to seal containers. The machine consists of an induction coil, which generates an electromagnetic field when energized with an alternating current. When the container with the foil liner passes through the electromagnetic field, the liner heats up due to eddy currents induced by the field.

Types of Induction Sealing Machines

There are several types of induction sealing machines available, each designed for specific applications. The most common types of induction sealing machines include:

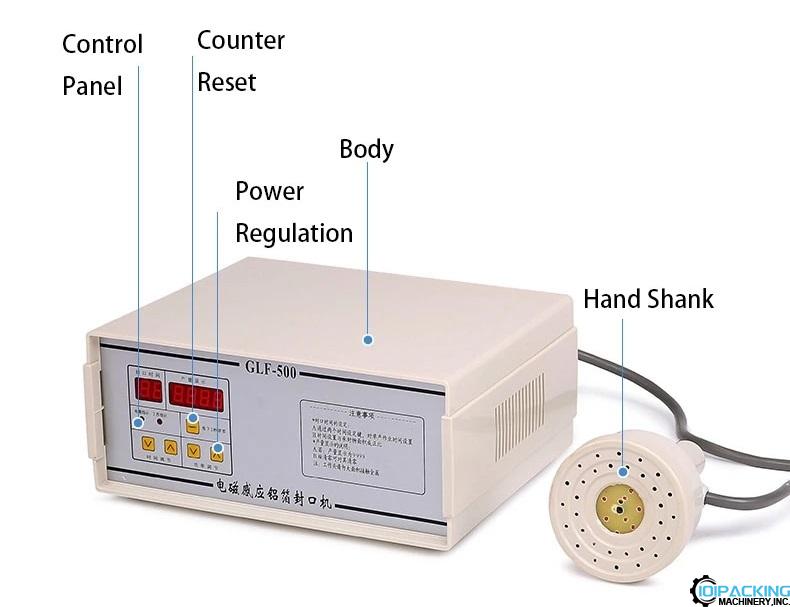

1.Handheld induction sealing machines: These machines are designed for sealing small volumes of containers and are ideal for businesses with low to medium production rates.

2.Benchtop induction sealing machines: These machines are designed for sealing moderate volumes of containers and are typically used in laboratory or small-scale production environments.

3.Automatic induction sealing machines: These machines are designed for high-volume production and are ideal for businesses with large-scale production needs. They offer a high degree of automation and can handle a wide range of container sizes and shapes.

Working Process of Induction Sealing Machines

Induction sealing machines work by creating an electromagnetic field that heats the foil liner in contact with the opening of the container. This heating causes the foil to bond to the rim of the container, creating a hermetic seal.

The working process of an induction sealing machine can be broken down into the following steps:

1.The container is filled with the product and the foil liner is placed on top of the container opening.

2.The container is then placed under the sealing head of the induction sealing machine.

3.The sealing head is activated, creating an electromagnetic field that heats the foil liner.

4.The heated foil liner bonds to the rim of the container, creating a hermetic seal.

Benefits of Induction Sealing Machines

Induction sealing machines offer several benefits, including:

1.Increased product shelf life: The hermetic seal created by induction sealing machines helps to preserve the quality and freshness of products, extending their shelf life and reducing product waste.

2.Improved product safety: The airtight seal created by induction sealing machines helps to prevent contamination, ensuring that products remain safe for consumption.

3.Reduced packaging costs: Induction sealing machines eliminate the need for additional packaging materials such as shrink bands or tamper-evident seals, resulting in less waste and a smaller environmental footprint.

Factors to Consider When Choosing an Induction Sealing Machine

When choosing an induction sealing machine, it's important to consider several factors, including:

1.Volume of containers to be sealed: The volume of containers to be sealed will determine the appropriate type of induction sealing machine for your business.

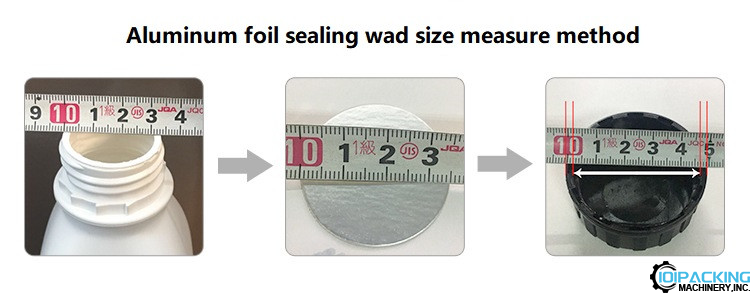

2.Size and shape of containers: The size and shape of the containers will affect the type of sealing head and the sealing parameters required.

3.Required sealing speed: The required sealing speed will determine the appropriate type of induction sealing machine and the level of automation required.

4.Cost: It's important to consider the cost of the machine, as well as the ongoing costs of maintenance, accessories, and operation.

Conclusion

Induction sealing machines offer a reliable and efficient way to seal containers for a variety of industries. Their ability to provide a secure and airtight seal helps to preserve the quality and freshness of products, and their versatility and customization options make them a valuable investment for businesses of all sizes. With their many benefits, it's no wonder that induction sealing machines continue to be a popular choice in the packaging industry.

Contact: 101Packing

Phone: +86 198 7511 8892

E-mail: info@101packing.com

Add: 5th Floor, Outside Building, Shangxue Tech Park, Jihua Road, Longgang District, Shenzhen,Guangdong,China