The capping machine industry has seen significant growth in recent years due to the increasing demand for automated packaging solutions in various industries. Here are some of the key trends in the capping machine business:

1.Increased Automation: Automation is a major trend in the capping machine industry, with more companies looking to automate their packaging processes to improve efficiency and reduce costs. As a result, there is a growing demand for advanced capping machines that can handle high-speed production and ensure consistent torque application.

2.Customization: Customization is another trend in the capping machine industry, as companies are looking for machines that can be customized to meet their specific packaging needs. Manufacturers are responding to this trend by offering highly versatile capping machines that can handle different container shapes and sizes, as well as different types of caps.

3.Sustainability: The trend towards sustainability is also impacting the capping machine industry, with companies looking for machines that can help reduce their environmental footprint. As a result, manufacturers are developing capping machines that use eco-friendly materials and require less energy to operate.

4.Integration: Integration is another trend in the capping machine industry, with more companies looking for machines that can be integrated with other packaging equipment to create a complete packaging line. Manufacturers are developing capping machines that can be easily integrated with other equipment, such as filling machines and labeling machines, to provide a complete packaging solution.

5.Internet of Things (IoT): The IoT is also impacting the capping machine industry, with more manufacturers developing machines that can be connected to the internet and provide real-time data on production performance. This allows companies to monitor production in real-time, identify any issues, and optimize production processes.

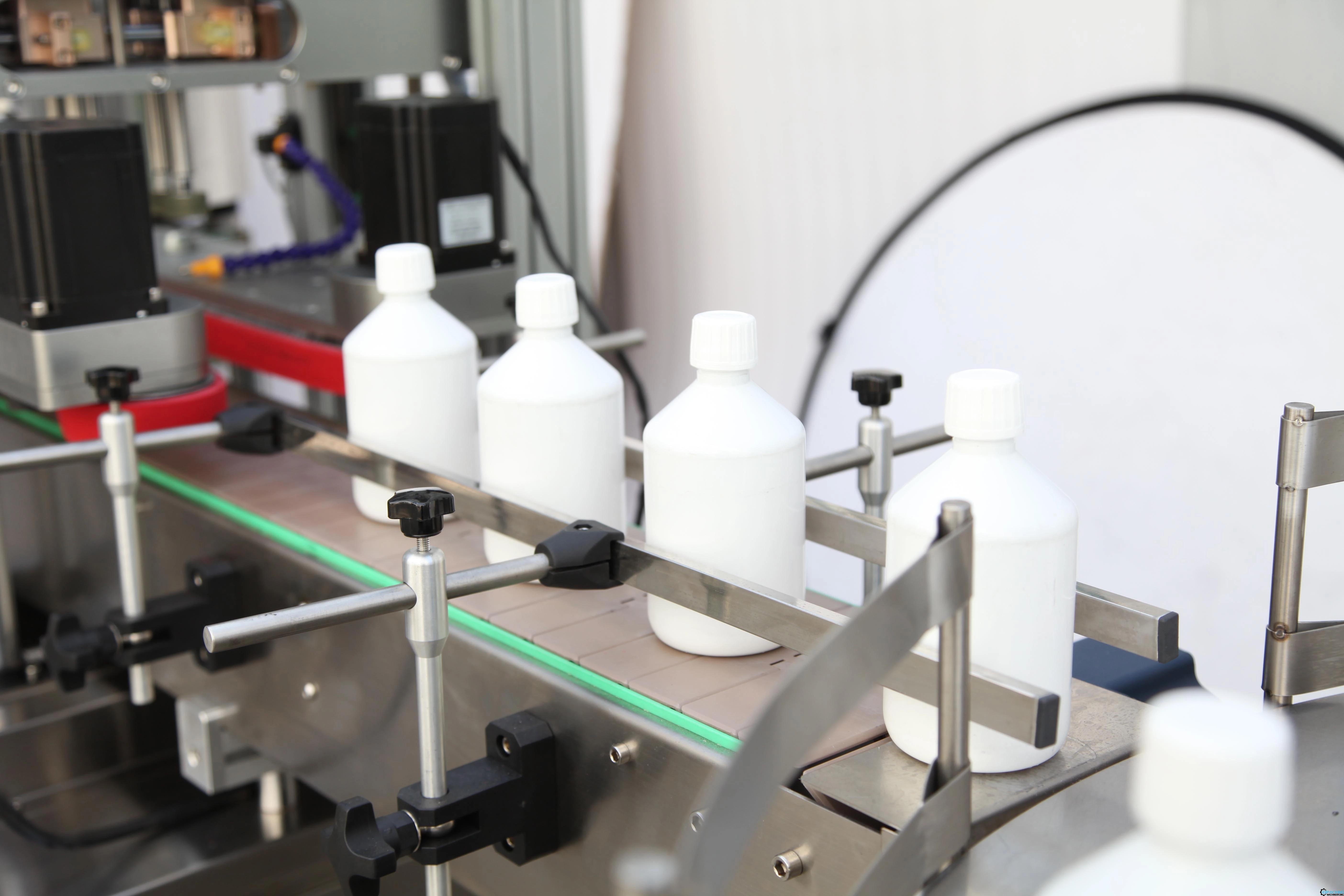

Capping machines are an essential tool in the manufacturing and packaging industries, providing efficient and reliable solutions for sealing caps onto containers. From bottles and jars to tubes and containers, capping machines come in different types to meet the diverse needs of various industries. In this article, we will explore the different types of capping machines, their benefits, and applications.

Types of Capping Machines:

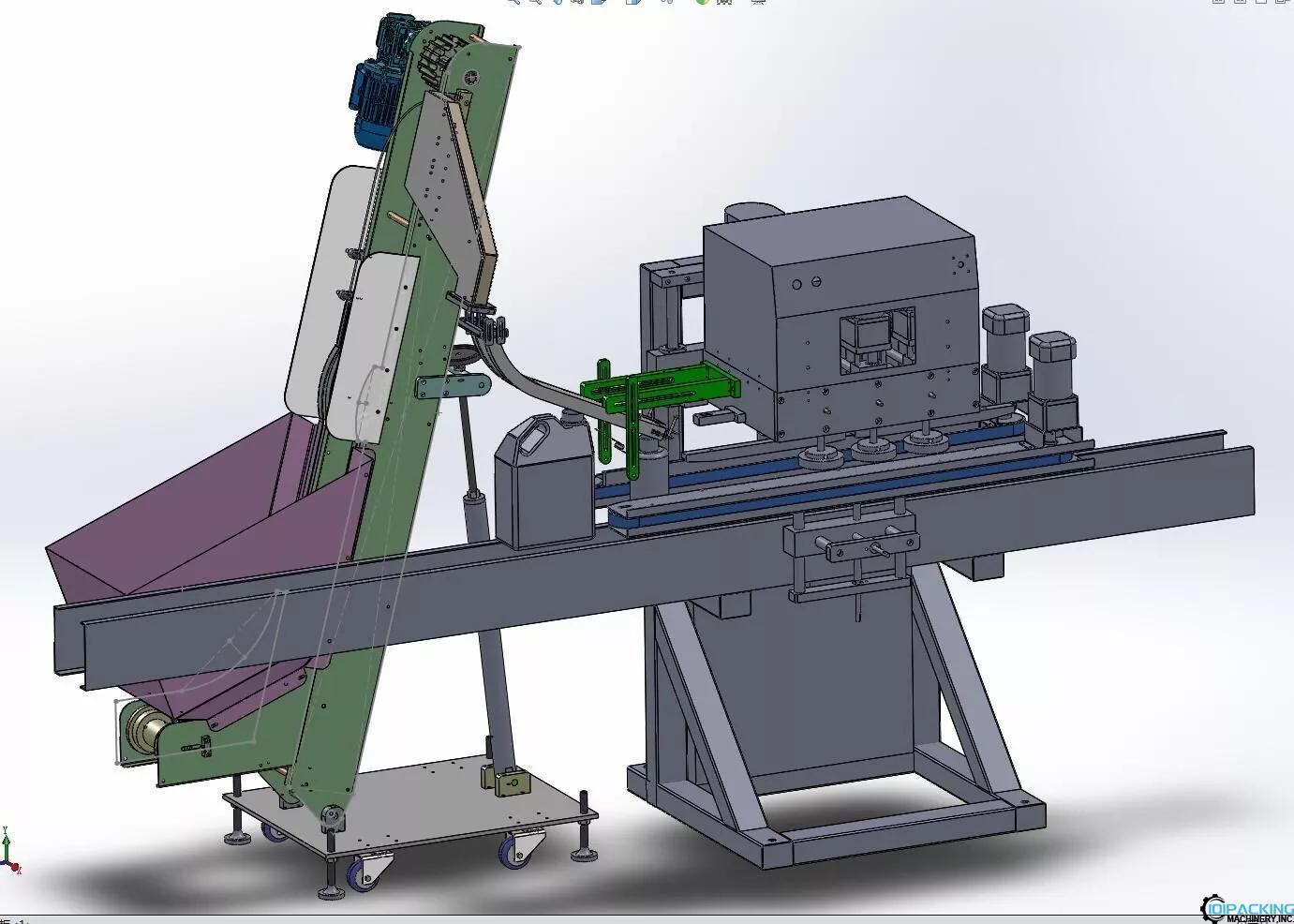

1.Automatic Capping Machines: Automatic capping machines are highly efficient and can handle a large volume of containers in a short time. They come with different types of capping heads, including spindle, chuck, and snap-on capping heads. Automatic capping machines are ideal for industries that require high-speed production and consistent torque application.

2.Semi-Automatic Capping Machines: Semi-automatic capping machines are more affordable and require manual loading and unloading of containers. They are ideal for small-scale production or applications that do not require high-speed production.

3.Inline Capping Machines: Inline capping machines are designed to work with existing production lines and can handle a range of container shapes and sizes. They are highly versatile and can be customized to meet specific production needs.

4.Rotary Capping Machines: Rotary capping machines are designed for high-speed production and can handle large volumes of containers. They come with different types of capping heads, including spindle, chuck, and snap-on capping heads.

Benefits of Capping Machines:

1.Increased Efficiency: Capping machines can handle a large volume of containers in a short time, reducing the need for manual labor and increasing production efficiency.

2.Consistent Torque Application: Capping machines can apply consistent torque to caps, ensuring that they are properly sealed onto containers and preventing leakage.

3.Versatility: Capping machines come in different types and can handle a range of container shapes and sizes, making them highly versatile and suitable for various industries.

4.Cost-Effective: Capping machines can reduce production costs by reducing the need for manual labor and improving production efficiency.

Applications of Capping Machines:

1.Food and Beverage Industry: Capping machines are widely used in the food and beverage industry for sealing caps onto bottles, jars, and containers of various sizes and shapes.

2.Pharmaceutical Industry: Capping machines are used in the pharmaceutical industry for sealing caps onto medicine bottles, vials, and other containers.

3.Cosmetic Industry: Capping machines are used in the cosmetic industry for sealing caps onto tubes, bottles, and jars of various sizes and shapes.

Conclusion:

Capping machines are an essential tool in the manufacturing and packaging industries, providing efficient and reliable solutions for sealing caps onto containers. With different types of capping machines available, it is essential to select the right type to meet the specific needs of each industry. By using capping machines, businesses can improve production efficiency, reduce production costs, and ensure consistent torque application for properly sealed containers.

Contact: 101Packing

Phone: +86 198 7511 8892

E-mail: info@101packing.com

Add: 5th Floor, Outside Building, Shangxue Tech Park, Jihua Road, Longgang District, Shenzhen,Guangdong,China