In the competitive world of product packaging, efficiency and accuracy play a crucial role in establishing a brand's presence. Cold wet glue labeling machines have emerged as a versatile solution for adhering labels to various products across industries. These machines offer a reliable and efficient method of labeling, ensuring a strong bond between the label and the packaging.

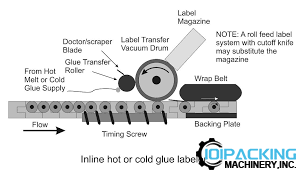

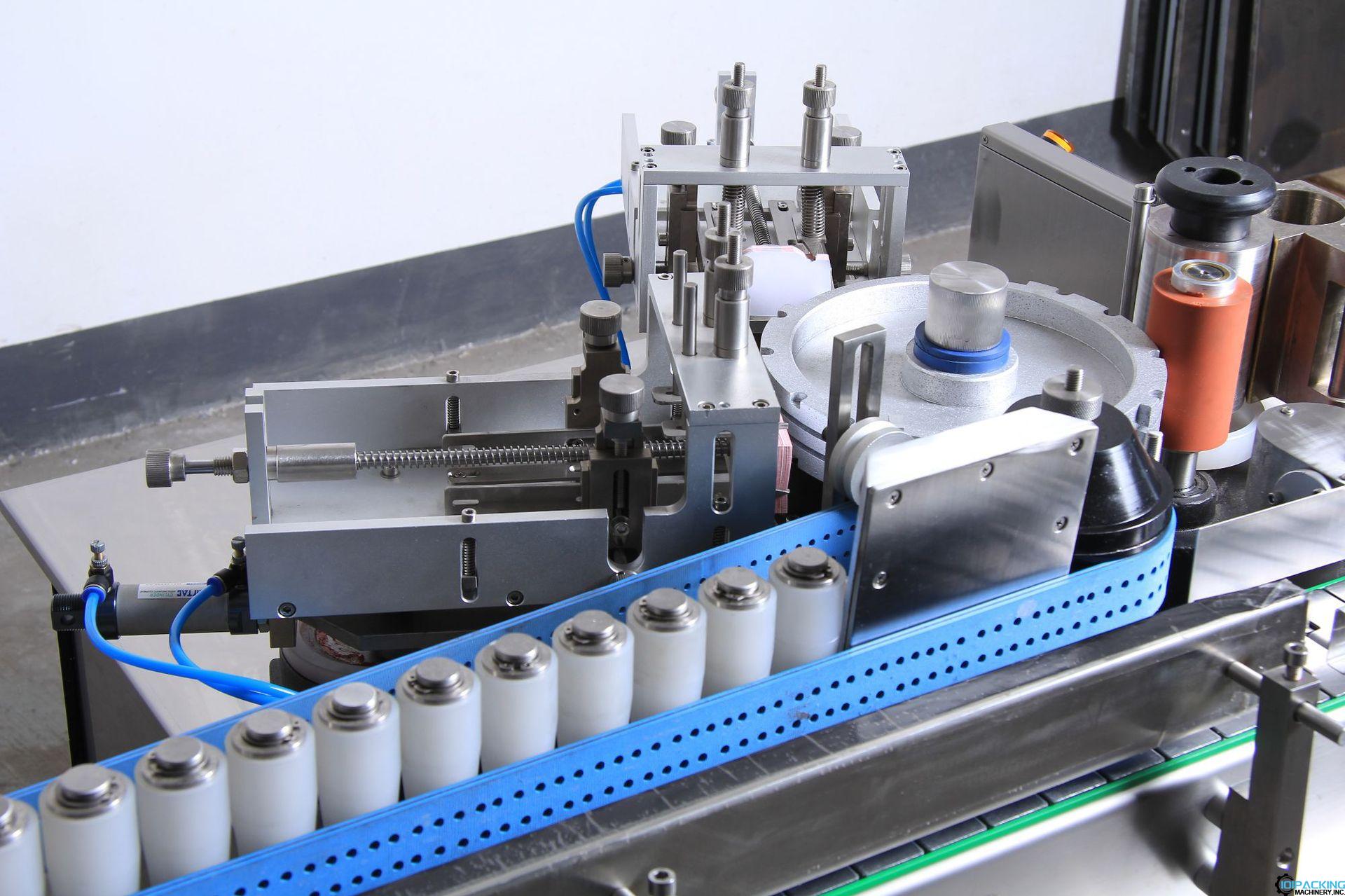

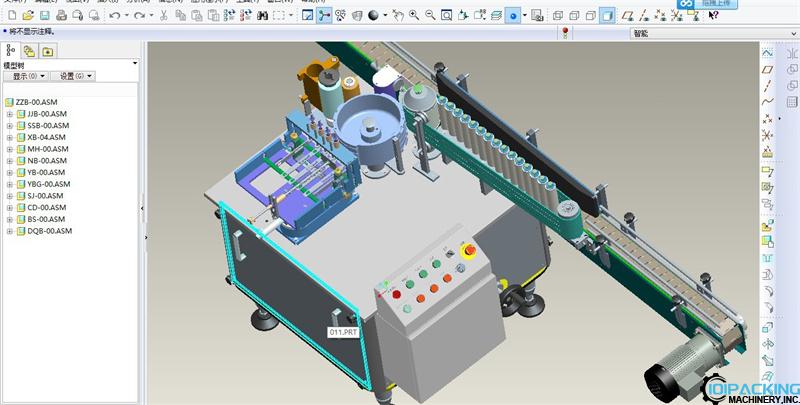

A cold wet glue labeling machine is a type of machine used in the packaging industry to apply labels on various products. It works by using a cold, wet glue adhesive to attach labels to items such as bottles, jars, cans, or boxes. The machine typically consists of a label magazine or roll, a glue application system, and a label application mechanism. The labels are fed into the machine, and the glue is applied to the labels as they pass through the machine. The labeled items are then automatically or semi-automatically placed on a conveyor or packaging line for further processing or packaging. Cold wet glue labeling machines are commonly used in industries such as food and beverage, pharmaceuticals, cosmetics, and household chemicals.

The working flow of a cold glue labeling machine typically involves the following steps:

1.Label Preparation: The labels, often in roll form, are loaded onto the labeling machine. The roll is placed on a dispenser or unwind station, ensuring proper alignment and tension for smooth label feeding.

2.Container/Product Handling: The containers or products to be labeled are introduced into the machine's handling system. This can be done manually or by an automatic container feeder, which positions them correctly for label application.

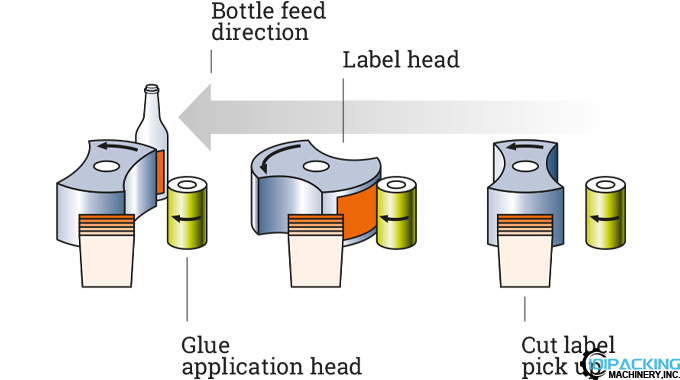

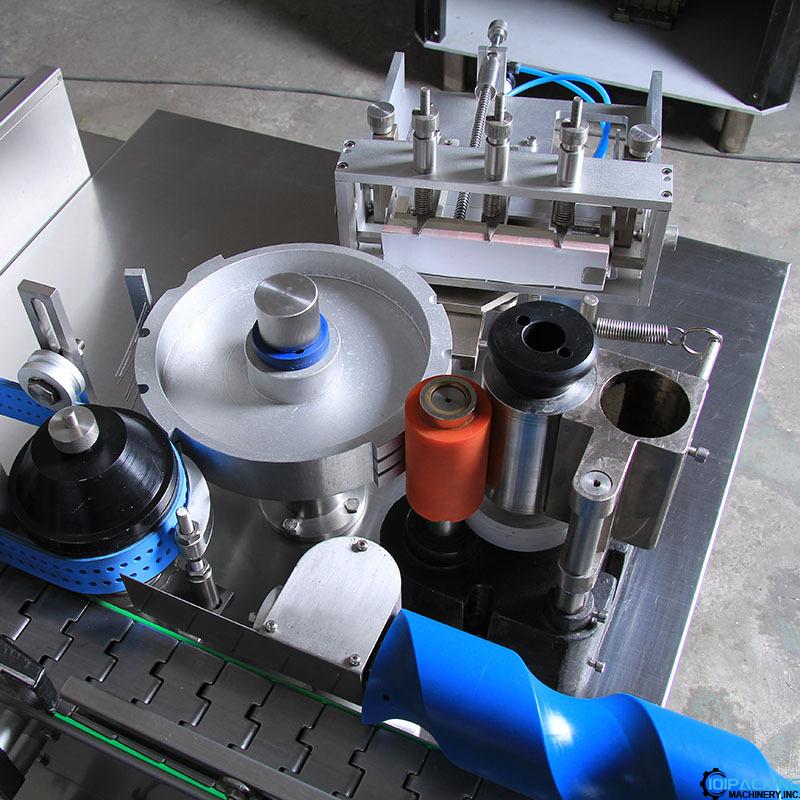

3.Label Dispensing: The labeling machine's mechanism collects a label from the roll and separates it from the backing material. The label is then held in place by a vacuum or suction mechanism or by the use of rubber pads.

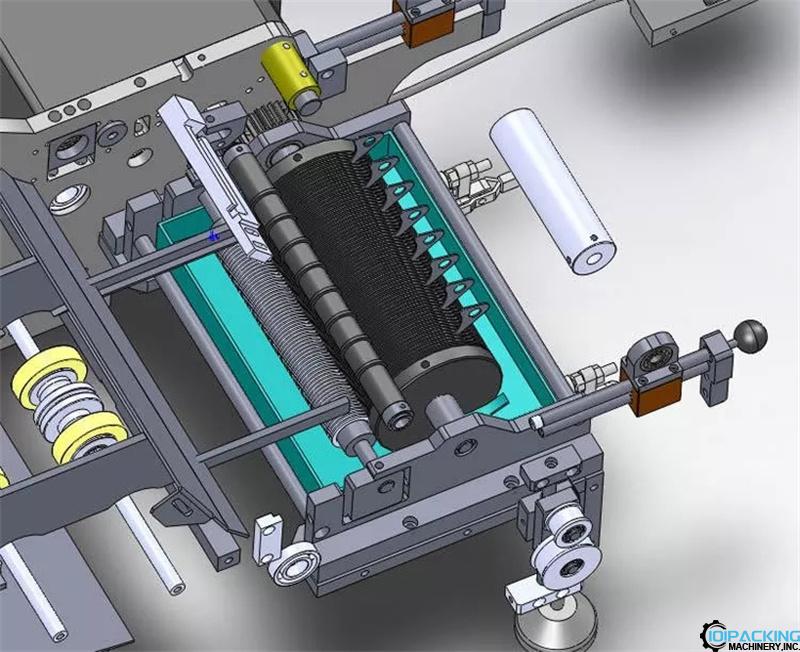

4.Glue Application: The labeling machine applies a precise amount of cold glue to the labeled area of the label. The glue can be applied using a glue roller or brush system, ensuring even distribution and controlled adhesive coverage.

5.Label Transfer: The labeled container/product is brought into contact with the glue-coated label. This can be done by a pressure-sensitive pad, a driven belt, or by a wrap-around mechanism, depending on the machine design and application requirements.

6.Label Pressing and Bonding: Once the label is in contact with the container/product, pressure is applied to ensure proper bonding and adhesion between the label and the surface. This can be achieved through a combination of belts, rollers, and/or pressing plates.

7.Label Drying/Curing: The glued labels need time to dry or cure, allowing the adhesive to securely bond with the container/product. Some labeling machines may include features like a drying tunnel or a heat source to accelerate this process.

8.Output and Ejection: The labeled containers/products are discharged from the machine's handling system, ready for the next stage of the production line or packaging process. Any excess label waste or trimmings are usually collected in a waste bin or conveyor for disposal.

What is cold wet glue?

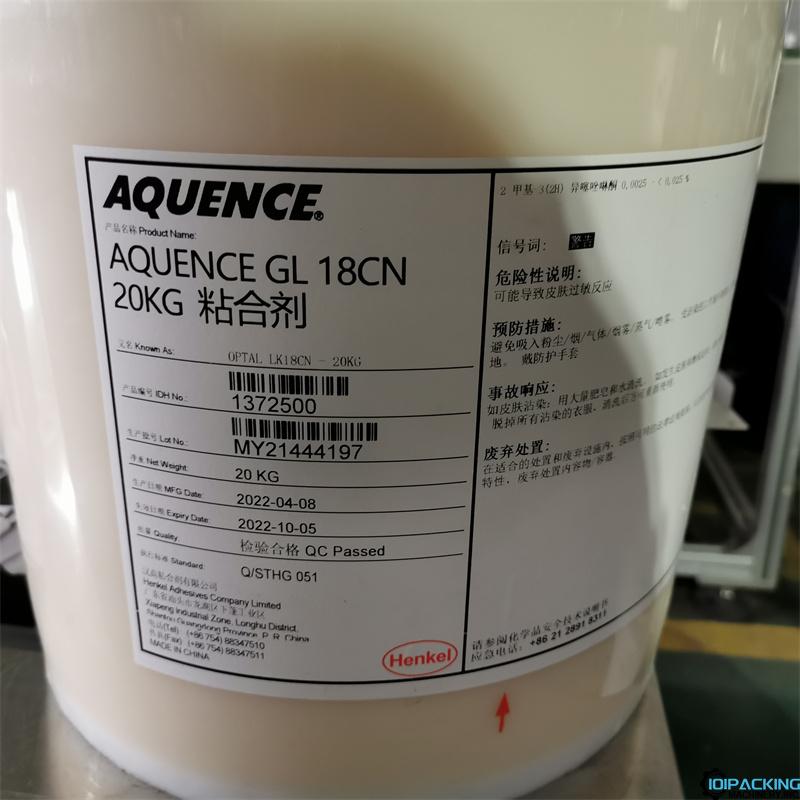

Cold wet glue, also known as cold glue or water-based adhesive, is a type of adhesive that is used in various industries for bonding and sealing applications. It is called "cold" because it does not require heat for activation or application. Instead, it relies on the moisture in the adhesive to create a bond.

Cold wet glue is typically made from natural or synthetic polymers that are dissolved or dispersed in water. The formulation may also include additives to enhance specific properties, such as viscosity, tack, and drying time. The water-based nature of the adhesive allows it to be easily applied and cleaned up with water.

Cold wet glue is commonly used in industries such as packaging, labeling, woodworking, bookbinding, and paper converting.

There are generally two main types of cold wet glue labeling machines:

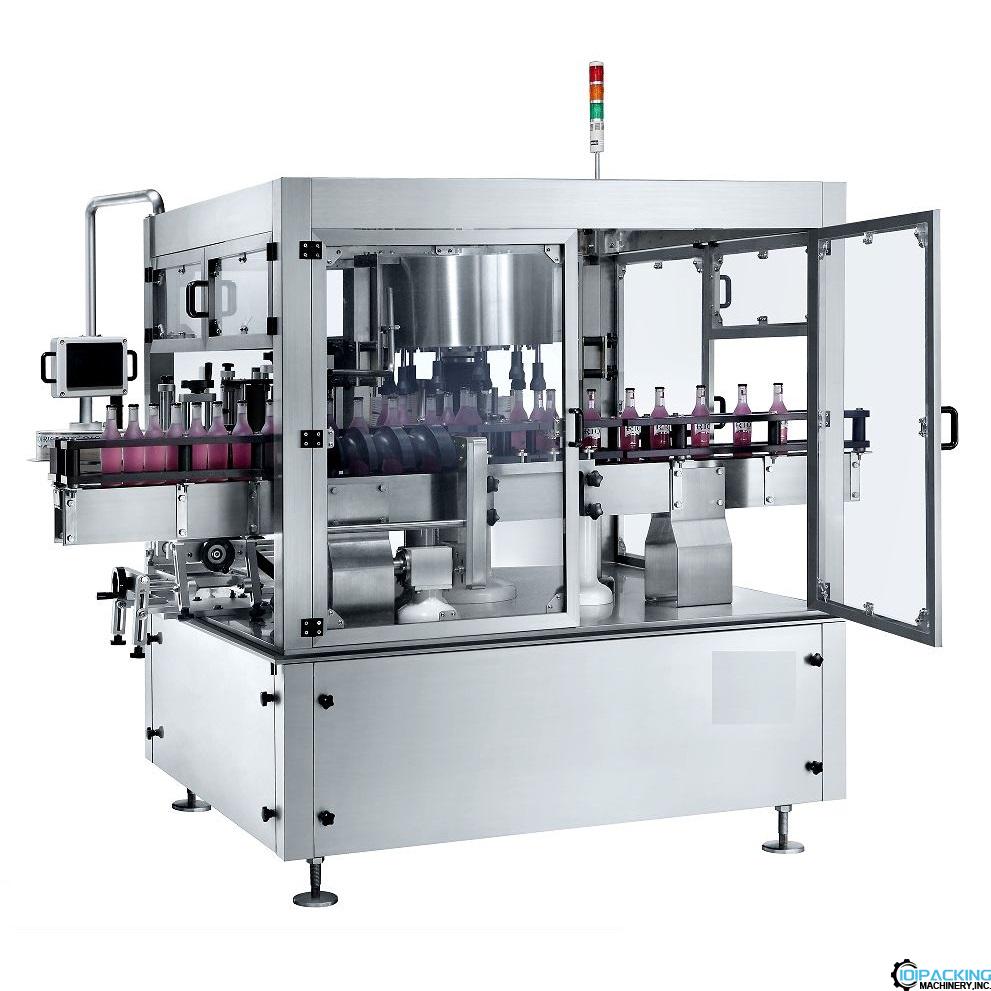

1.Rotary Cold Wet Glue Labeling Machine: This type of machine is designed with a rotary system where the labeled items are rotated to apply the labels. It is suitable for high-speed labeling applications, as it can label multiple items simultaneously on a rotating platform.

2.Linear Cold Wet Glue Labeling Machine: This type of machine operates in a linear or straight-line manner, where the labeled items move in a linear path to apply the labels. It is commonly used for labeling smaller or irregularly shaped products and is suitable for lower-speed labeling applications.

3.Desktop wet cold glue labeling machine

A desktop cold glue labeling machine, also known as a tabletop cold glue labeler, is a compact and versatile machine designed for applying cold glue labels to various products. It is typically used in small-scale production settings where space is limited.

The desktop cold glue labeling machine operates by dispensing a water-based adhesive onto labels, which are then applied to products as they pass through the machine. The labels are precisely positioned and pressed onto the products for optimal adhesion.

In addition to these two main types, there may be variations or customized versions of cold wet glue labeling machines available in the market to cater to specific industry requirements.

Application of Cold Glue Labels:

The application of cold glue labels involves the use of cold glue labeling machines. These machines dispense the water-based adhesive onto the labels, either through multiple glue rollers or via precise nozzle systems. The labeled products then pass through a glue station where the labels are applied with pressure or rollers, ensuring proper adhesion.

Versatility and Benefits:

Cold wet glue labeling machines are widely used in industries such as food and beverage, pharmaceuticals, cosmetics, and household chemicals. The flexibility of these machines allows for labeling a wide range of products, including bottles, jars, cans, and boxes. Some of the key benefits of utilizing these machines are:

1.Strong Bond: Cold wet glue labeling machines employ a cold adhesive technique that creates a robust bond between the label and the product. This ensures that the label remains intact throughout transportation, storage, and usage.

2.Cost-effective: Compared to other labeling methods, the cold wet glue technique is relatively cost-effective. This factor makes it a preferred choice for companies with high-volume labeling needs.

3.Customization: Cold wet glue labeling machines offer a high degree of customization, enabling businesses to place labels at specific locations on products. This customization option helps enhance branding and product information visibility.

Conclusion:

In a highly competitive market, effective product labeling plays a vital role in attracting customers and establishing brand identity. Cold wet glue labeling machines provide a reliable and versatile solution for businesses across various industries. With their strong bond, cost-effectiveness, and customization options, these machines ensure accurate and efficient labeling of products. Whether it is a small business or a large-scale manufacturing unit, investing in a cold wet glue labeling machine can significantly streamline the packaging process, enhance brand recognition, and ultimately contribute to the success of a company.

Contact: 101Packing

Phone: +86 198 7511 8892

E-mail: info@101packing.com

Add: 5th Floor, Outside Building, Shangxue Tech Park, Jihua Road, Longgang District, Shenzhen,Guangdong,China