A Comprehensive Guide to Choosing the Best Solution for Your Labeling Needs"

Labeling machines have become an essential tool for businesses looking to streamline their labeling processes and increase productivity. They are used to apply labels to products, packaging, and containers in a range of industries, from food and beverage to pharmaceuticals and cosmetics. In this article, we will provide you with the ultimate guide to labeling machines, including types, benefits, and factors to consider when choosing a machine for your business.

Types of Labeling Machines

There are several types of labeling machines available, each designed for specific labeling applications. Some of the most common types of labeling machines include:

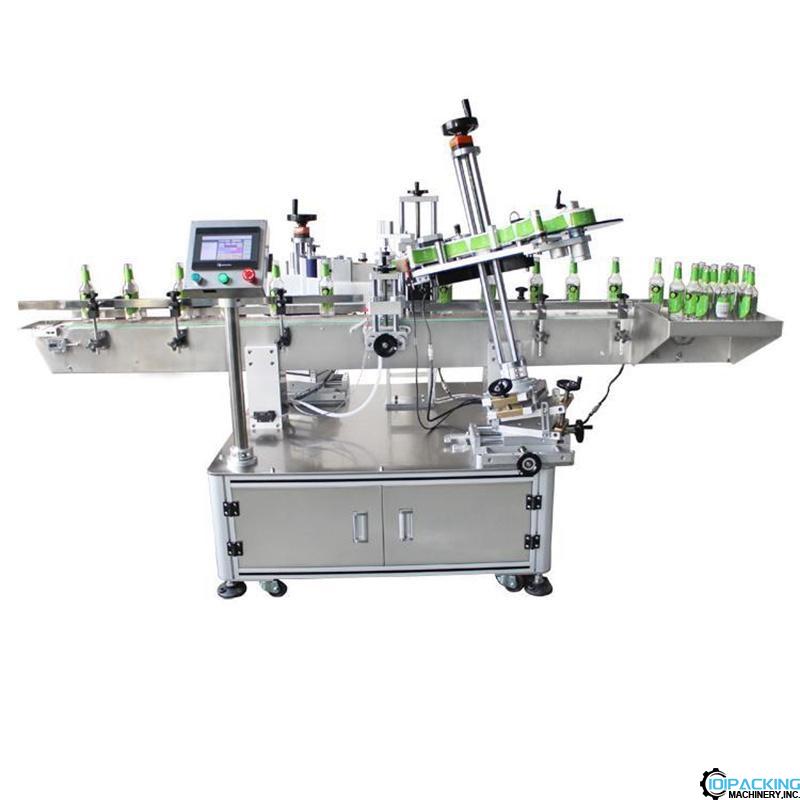

1.Pressure-sensitive labeling machines

Pressure-sensitive labeling machines use a roll of self-adhesive labels that are applied to the product or packaging by a pressure-sensitive applicator. These machines are commonly used for applying labels to bottles, jars, and other cylindrical or curved products.

2.Sleeve labeling machines

Sleeve labeling machines apply a heat-shrink sleeve label to a product or packaging, creating a 360-degree label that covers the entire product. These machines are often used for packaging products with irregular shapes or for creating tamper-evident seals.

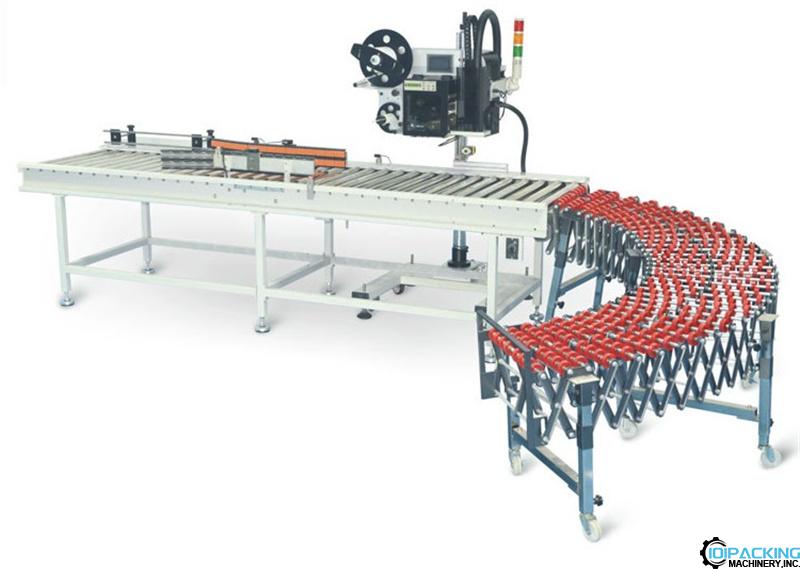

3.Print and apply labeling machines

Print and apply labeling machines are designed to print labels on demand and apply them to products or packaging. These machines are ideal for businesses that need to print and apply variable data, such as expiration dates, lot numbers, or barcodes.

4.Wrap-around labeling machines

Wrap-around labeling machines apply a label that wraps around the entire circumference of a product or packaging. These machines are often used for labeling cans, bottles, or jars with a single label that provides all the necessary information.

Benefits of Labeling Machines

Labeling machines offer several benefits for businesses looking to improve their labeling processes and increase productivity. Some of the key benefits of labeling machines include:

1.Increased labeling accuracy

Labeling machines offer precise and accurate label placement, ensuring that labels are applied correctly and consistently. This reduces the risk of misapplication or wasted labels and ensures that products are labeled accurately and efficiently.

2.Improved productivity

Labeling machines can apply labels quickly and efficiently, reducing the time and labor required for manual labeling. This increases productivity and allows businesses to label more products in less time.

3.Compliance with regulations

Many industries have specific labeling requirements, such as nutritional information, allergy warnings, or ingredient lists. Labeling machines can help businesses comply with these regulations by applying accurate and consistent labels that meet industry standards.

4.Reduced costs

Labeling machines can help businesses reduce costs by eliminating the need for manual labeling and reducing waste due to misapplication or damaged labels. They can also help businesses avoid costly fines or recalls by ensuring that products are labeled accurately and meet industry standards.

Factors to Consider When Choosing a Labeling Machine

When choosing a labeling machine for your business, there are several factors to consider, including:

1.Labeling requirements

Consider your labeling requirements, including label dimensions, materials, and types. Choose a labeling machine that can handle your specific labeling needs.

2.Product type and packaging

Consider the type of product or packaging you need to label. Choose a labeling machine that is designed for your specific product or packaging type.

3.Production volume

Consider your production volume and choose a labeling machine that can handle your throughput requirements.

4.Labeling accuracy

Choose a labeling machine that offers precise and accurate label placement, ensuring that labels are applied correctly and consistently.

5.Budget

Consider your budget and choose a labeling machine that offers the best balance of features, performance, and cost.

Conclusion

Labeling machines are an essential tool for businesses looking to improve their labeling processes and increase productivity. With a range of types available, including pressure-sensitive, sleeve, print and apply, and wrap-around labeling machines, businesses can find the perfect solution for their specific labeling needs. By considering factors such as labeling requirements, product type and packaging, production volume, labeling accuracy, and budget, businesses can choose a labeling machine that offers the best balance of features, performance, and cost.

Continuous labeling machines are also available for businesses with high-volume labeling needs. These machines are designed to apply labels continuously, without any interruption in the labeling process. They can handle a range of label materials and sizes, making them ideal for businesses in a range of industries.

In conclusion, labeling machines offer numerous benefits for businesses looking to improve their labeling processes and increase productivity. By choosing the right labeling machine for your specific needs and considering factors such as labeling requirements, product type and packaging, production volume, labeling accuracy, and budget, businesses can achieve accurate and efficient labeling and reduce costs in the long term. Continuous labeling machines can also provide a high-volume solution for businesses with ongoing labeling needs. With the right labeling machine in place, businesses can streamline their labeling processes and focus on growing their business.

Contact: 101Packing

Phone: +86 198 7511 8892

E-mail: info@101packing.com

Add: 5th Floor, Outside Building, Shangxue Tech Park, Jihua Road, Longgang District, Shenzhen,Guangdong,China