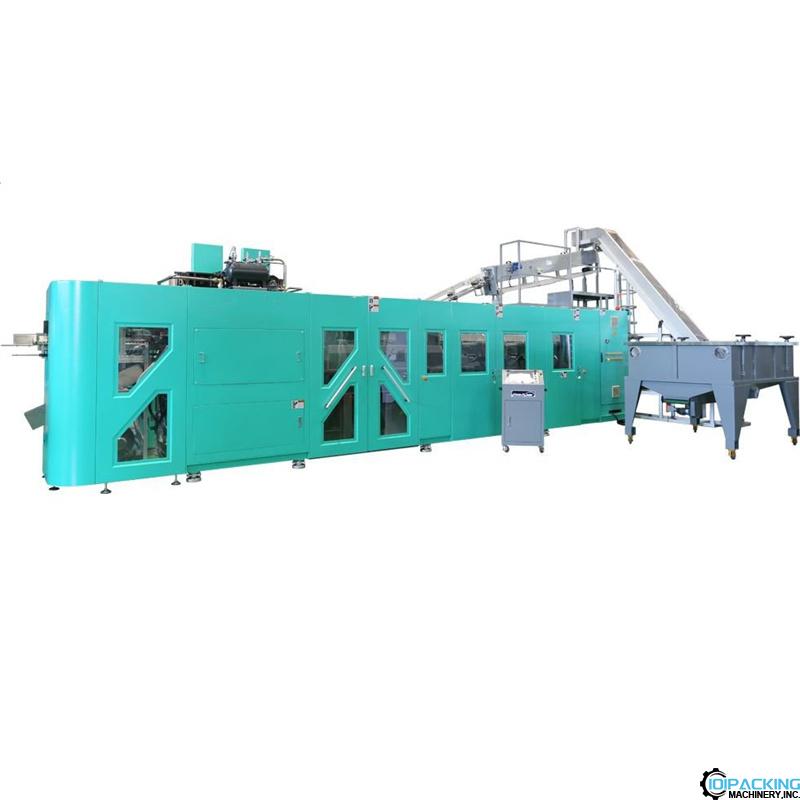

Automatic PET bottle 12 cavities high speed blowing machine

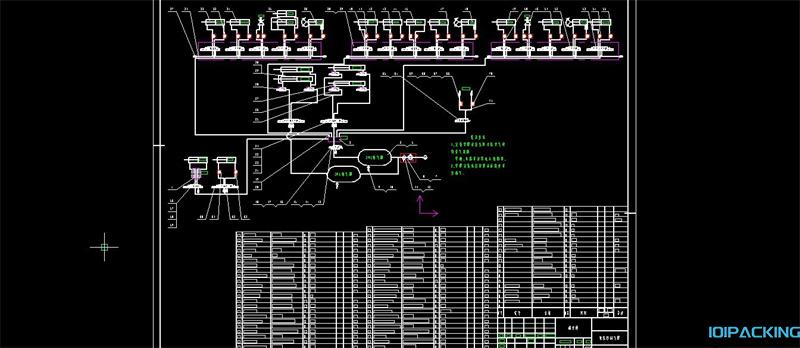

High speed linear type 12 cavities bottle blowing machine fully automatic plastic bottle making line 10000 bottle per hour

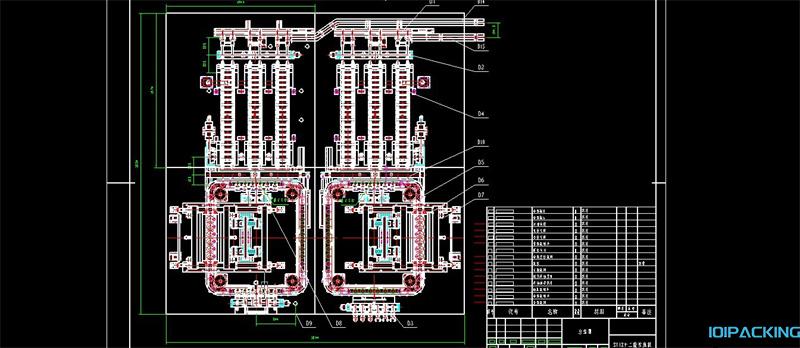

Number of blowing heads: 12 cavities;

Production capacity: 10,000 bottles / hour (500ML / water bottle);

Main components and working principle:

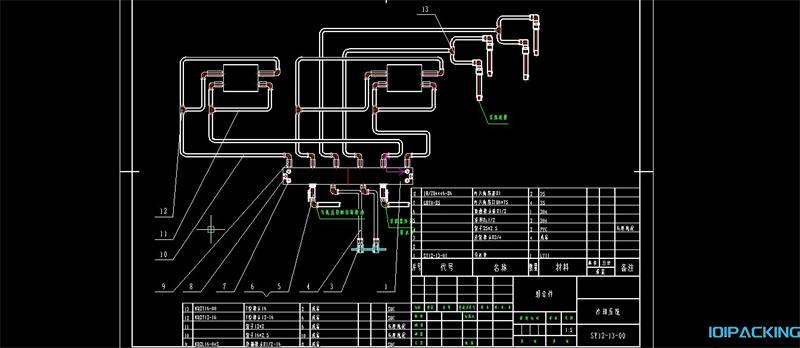

A 12-cavity blow molding machine is mainly used for blow molding of various plastic bottles. It uses the far-infrared lamp as the heating source, drives the sprocket through the servo motor to drive the preform to run in the heater, and then enters the cavity to pass the high-pressure gas stretch blow molding. The components of the blow molding machine should be stable, coordinated, and accurate. The control system is responsive and the instructions are clear and accurate. With the matching mold can form qualified products. With the touch screen operation, man-machine dialogue can be realized, and the running state of the device is clear at a glance. The main electrical components (touch screen, etc.) are all brand-name products. The main cylinders of the power components are mainly SMC, which ensures the equipment is stable and durable.

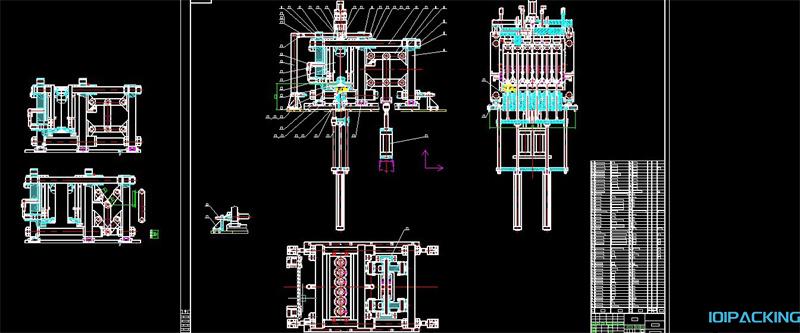

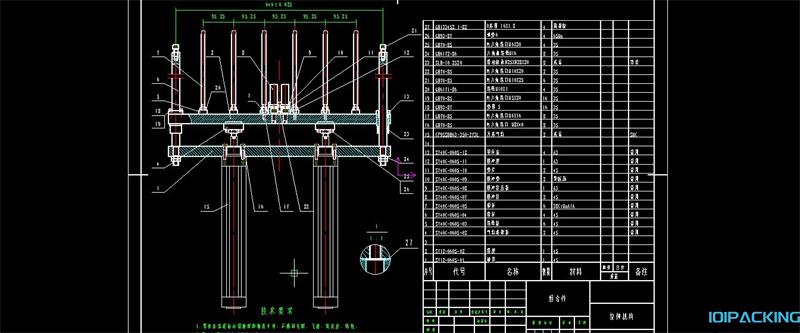

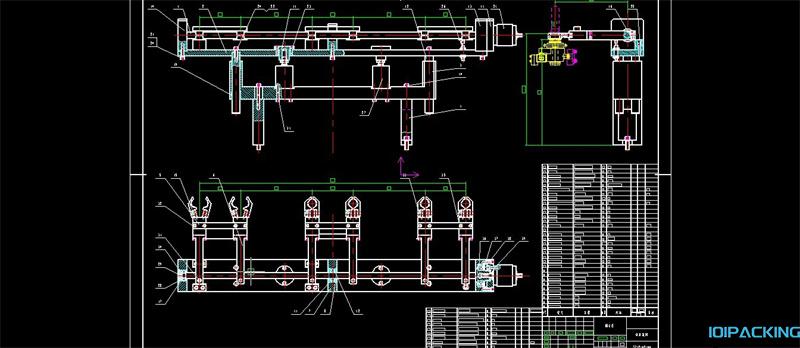

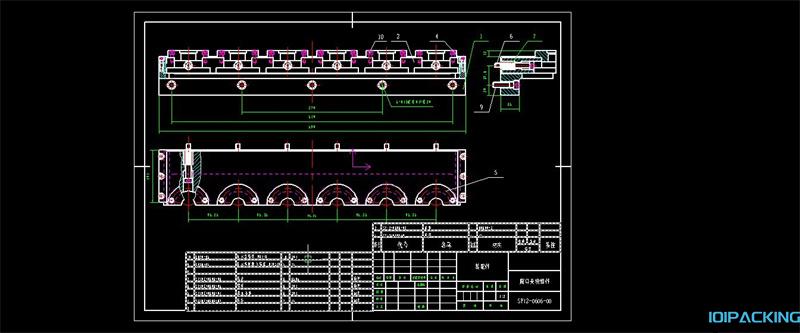

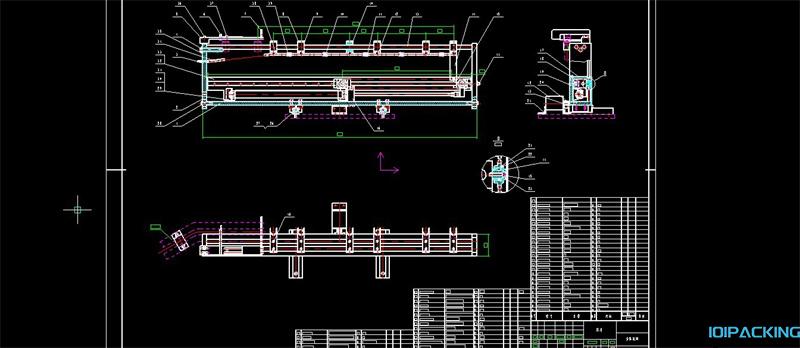

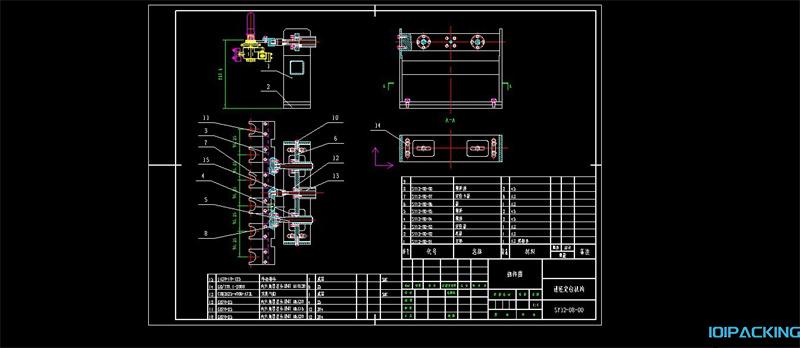

A six blow molding machine mainly includes the following components:

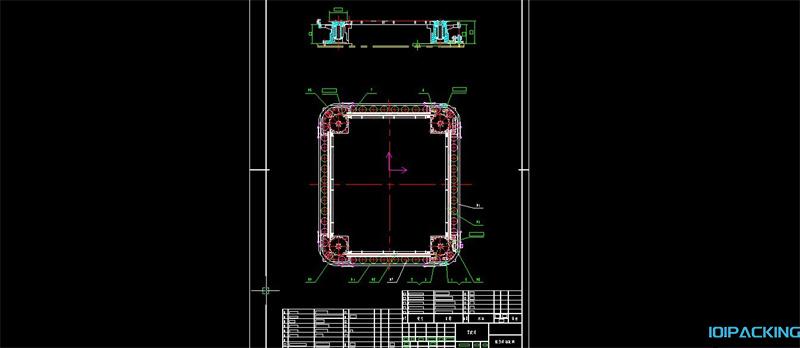

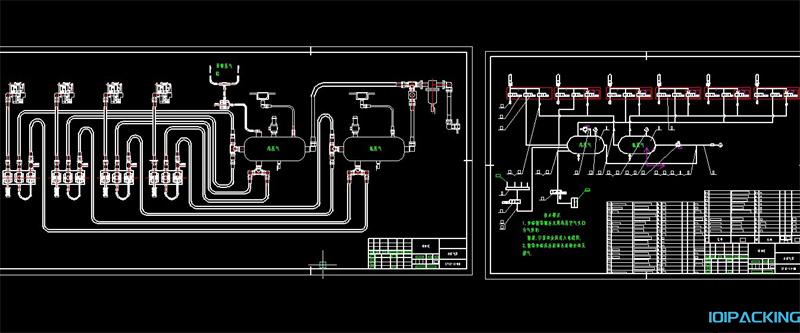

Lifting machine, rationalizing machine, flipping bottle feeding mechanism, turning out bottle discharging mechanism, heating device, stretching and clamping mechanism, chain transmission mechanism, electronic control system, high and low pressure pneumatic system, rack and sealing window.

1. Hoist: The motor drives the baffle belt to run, and the preform in the hopper is smoothly raised and transported to the texture machine.

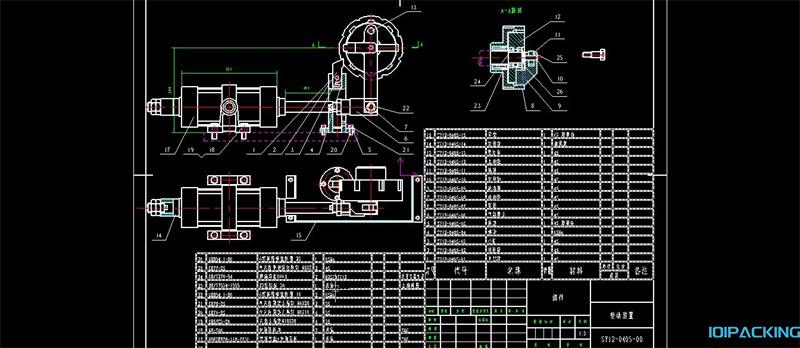

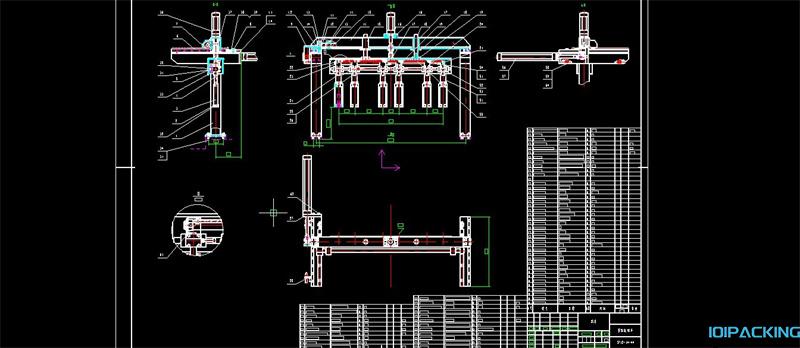

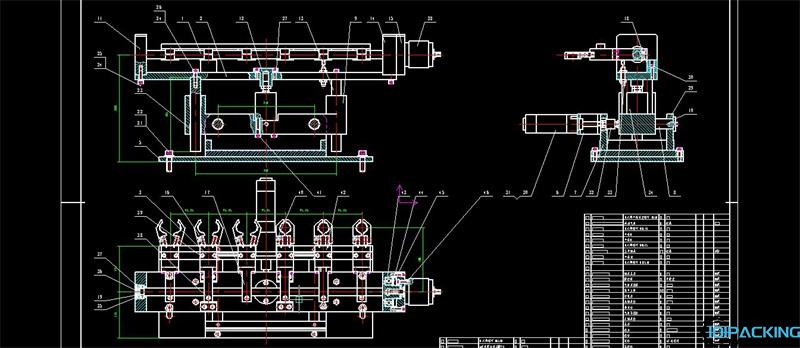

2. Texture machine: The texture machine mainly arranges the disordered preforms into the same order, and prepares for the next delivery to the bottle blowing machine. There are two rollers on the texture machine, which are driven by the motor, and the preforms are turned up and down until they are neatly arranged. 3. Flip the bottle feeding mechanism: Turn the cylinder to send the preform directly to the installation position of the chain transmission mechanism. The opening and closing of the bottle mouth clamp is controlled by a pneumatic clamp, and the turning cylinder controls the inversion of the bottle mouth clamp block. The lower cylinder is a lifting and lowering bottle feeder, so that the mechanism can be turned upside down, and a waist hole is formed on each of the mounting components for easy adjustment.

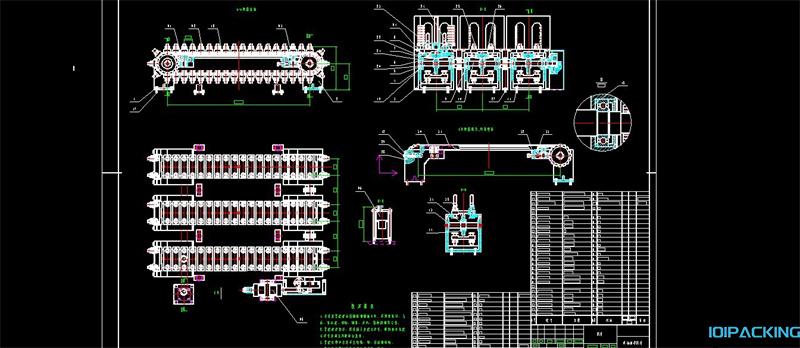

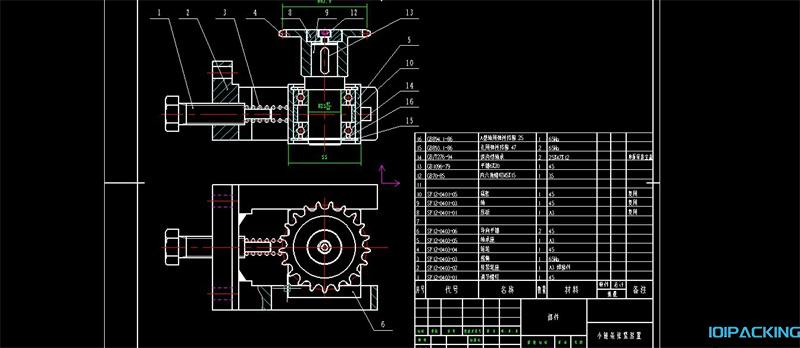

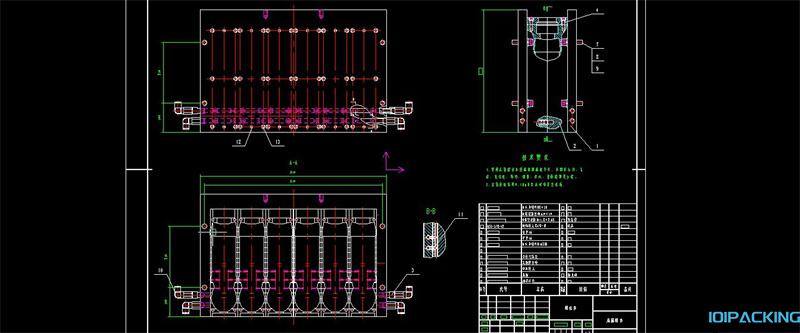

4. Chain drive mechanism: The preform is placed on the bottle holder. There are two transmission routes, two independent motors, and one servo motor drives the large chain to drive the bottle holder to revolve on the frame. The blank member, the heating device, the mold clamping mechanism, and the bottle discharging member. Second, the small chain drives the bottle holder to rotate, so that the preform can be evenly heated.

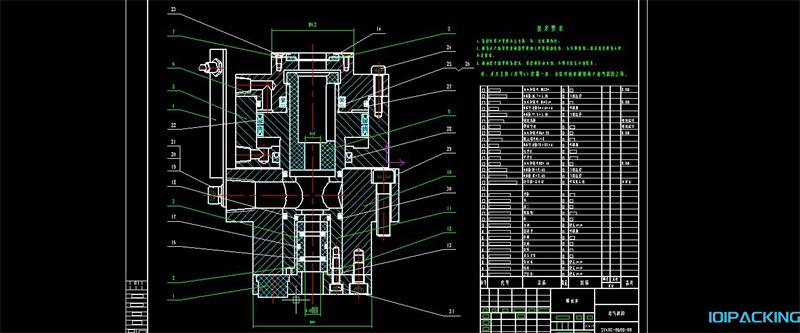

5. Heating device: The heating device is equipped with a tube-type infrared lamp, which is heated by infrared rays to perform special radiation output. However, in order to properly heat the preform, it is necessary to adjust the height of the heater device and the distance between the heater device and the conveyor line. Stop the operation of the machine and insert several preforms into the bottle holder. Manually rotate the transport rail and pass through the inside of the heater unit. After doing so, the heater is adjusted in the following order according to the shape and size of the preform.

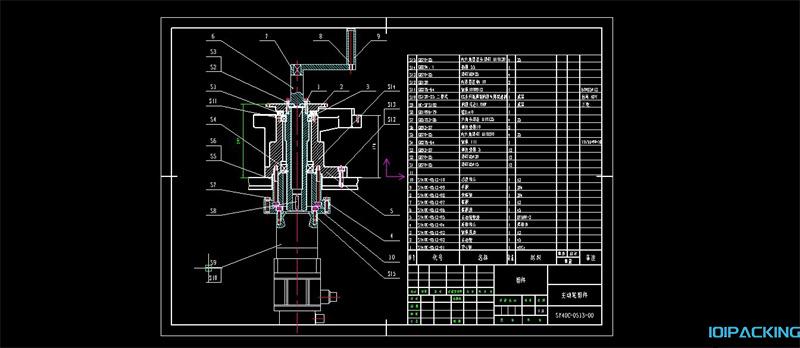

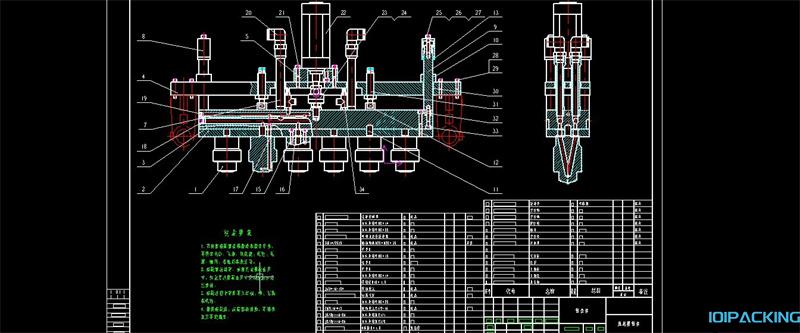

6. Stretch clamping mechanism: This mechanism is a key part of the blow molding machine. After the heated preform arrives, three cylinders act in sequence, complete the mold clamping, and form a high pressure gas preform in the mold. The mold mechanism has a water cooling system, which reduces the local uneven heating of the mold and causes deformation. The cavity of the mold can be replaced, so that bottles of different shapes can be blown. The extension rod acts as a stretch guide, without which it affects the quality of the bottle. The delay stop acts as a positioning and protection.

7. Flip the bottle out mechanism: The roll-out mechanism is similar to the roll-in mechanism, and the finished bottle is taken out. Install the same number of clamps as the blow cavity. Install 6 sets, the center position is the same for any mold, and adjust if necessary. When the conveyor belt is taken out mechanically, depending on the shape of the new product, it may be necessary to adjust the height of the take-out rail and the conveyor belt.

Contact: 101Packing

Phone: +86 198 7511 8892

E-mail: info@101packing.com

Add: 5th Floor, Outside Building, Shangxue Tech Park, Jihua Road, Longgang District, Shenzhen,Guangdong,China