What is BIB filling machine?

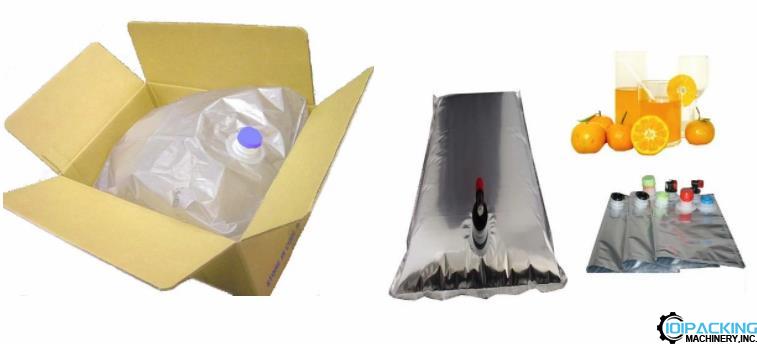

A BIB (Bag-in-Box) filling machine is a device used for packaging liquids, typically beverages such as wine, fruit juices, or water, into Bag-in-Box containers. Bag-in-Box is a type of packaging that consists of a flexible bag, usually made of plastic or metallized film, placed inside a rigid cardboard box.

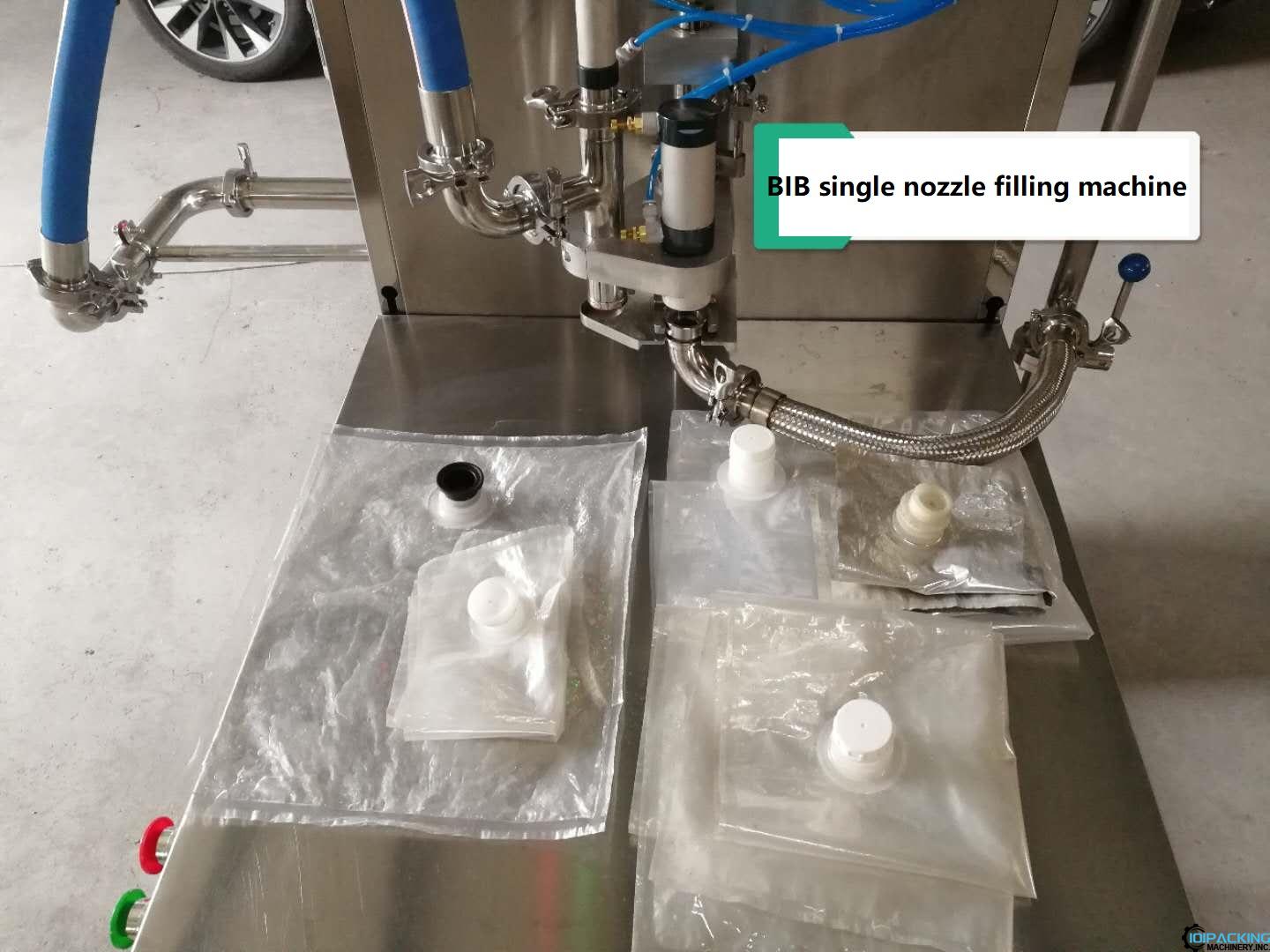

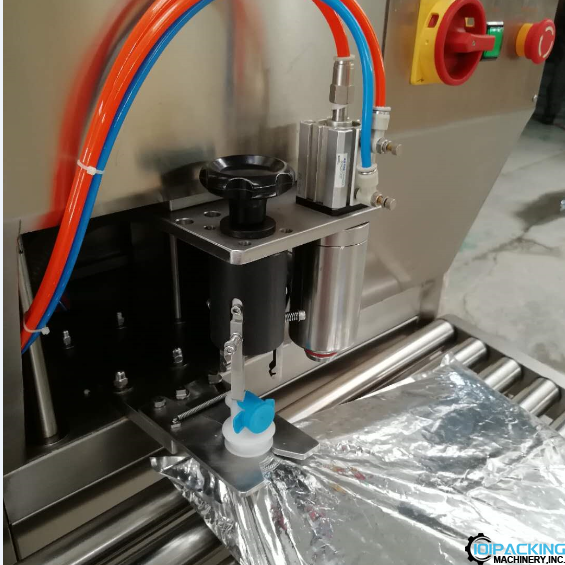

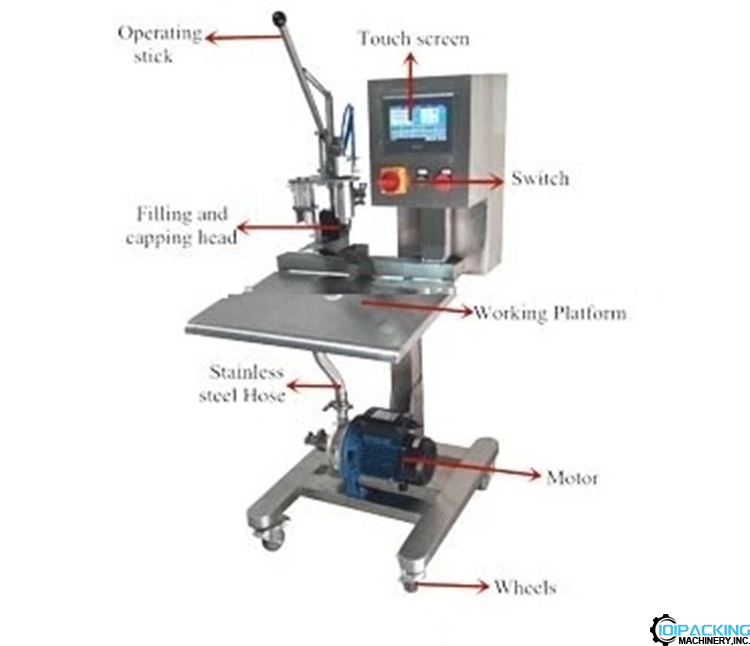

The BIB filling machine automates the process of filling these bags with the desired liquid. It typically consists of several components, including a product supply system, a bag handling system, a filling mechanism, and a sealing system.

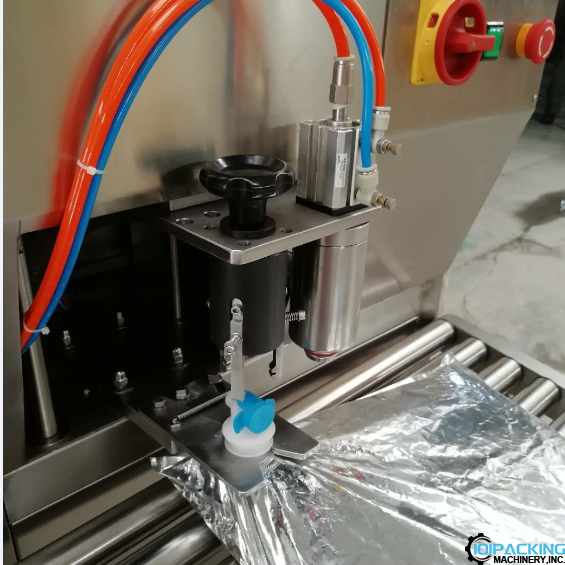

The process begins by positioning an empty bag inside the filling machine. The product supply system, which may include pumps or gravity feed systems, transfers the liquid into the bag through a filling nozzle. The filling mechanism controls the flow rate and volume of the liquid to ensure accurate filling.

Once the bag is filled, the sealing system seals the bag to prevent leakage. This can be done through various methods, such as heat sealing or ultrasonic sealing. The filled and sealed bag is then placed into a cardboard box, which provides structural support and protection during transportation and storage.

BIB filling machines are commonly used in commercial settings, such as wineries, beverage manufacturing plants, and food service establishments. They offer several advantages, including efficient packaging, extended product shelf life, easy dispensing, and reduced packaging waste compared to traditional bottles or cans.

The Advantages of Bag-in-Box Filling Machines

In today's fast-paced world, efficient and reliable packaging solutions are vital for industries that deal with liquid products. Bag-in-Box (BIB) filling machines have emerged as a game-changer, revolutionizing the way beverages such as wine, fruit juices, and water are packaged. This article explores the numerous advantages of BIB filling machines, shedding light on their functionality, benefits, and their positive impact on packaging operations.

1.Streamlined Packaging Process:

BIB filling machines automate the packaging process, significantly increasing productivity and efficiency. These machines can handle large volumes of liquids, allowing for high-speed filling, sealing, and boxing. The streamlined process minimizes human error and ensures consistent results, saving time and labor costs.

2.Precise and Accurate Filling:

One of the key benefits of BIB filling machines is their ability to provide precise and accurate filling. These machines are equipped with advanced controls that measure and regulate the flow rate and volume of the liquid being filled. This ensures that each bag is filled to the desired level, maintaining product consistency and minimizing wastage.

3.Extended Shelf Life:

BIB packaging offers superior protection against oxygen, light, and contaminants, resulting in an extended shelf life for the packaged liquids. The bag acts as an airtight barrier, preventing oxidation and maintaining the product's freshness and quality. With reduced exposure to external factors, beverages packaged in BIB containers have a longer shelf life compared to traditional packaging formats.

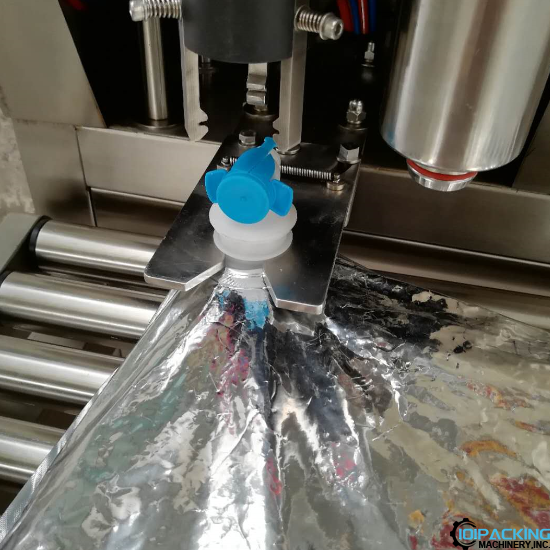

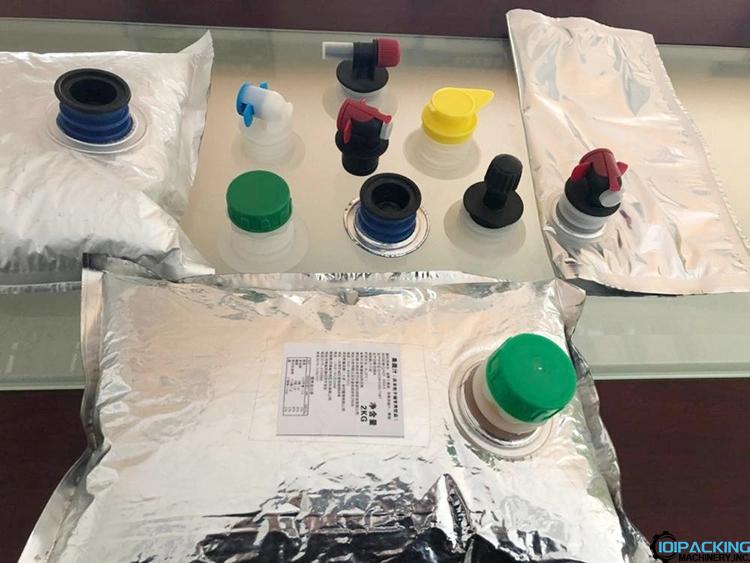

4.Convenient Dispensing:

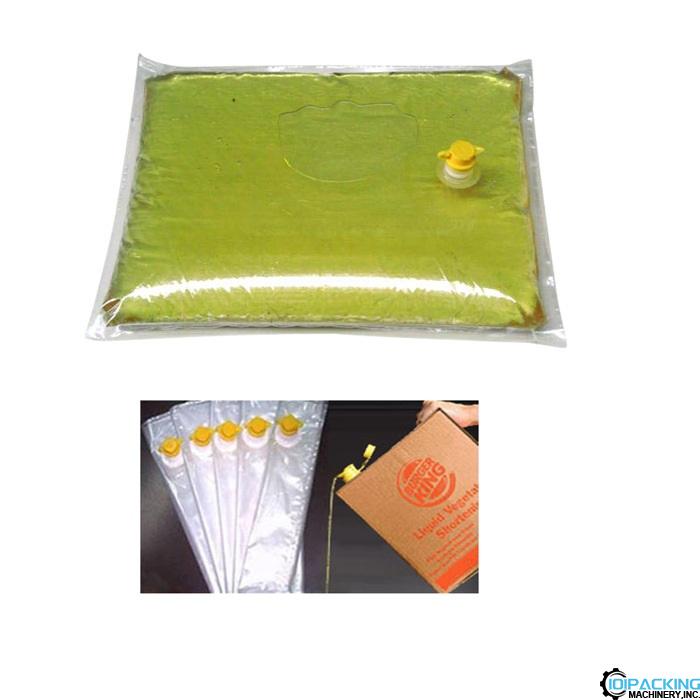

BIB packaging incorporates an easy-to-use dispensing system, making it convenient for both commercial and consumer use. The bags are typically equipped with a built-in tap or valve, allowing for controlled dispensing without the need for additional equipment. This feature is particularly beneficial for food service establishments, catering companies, and events where large quantities of beverages need to be served quickly and efficiently.

5.Reduced Packaging Waste:

In today's eco-conscious society, minimizing packaging waste is a top priority for businesses. BIB filling machines contribute to sustainable packaging practices by reducing waste. The flexible bags used in BIB packaging require less material compared to traditional bottles or cans, resulting in a smaller carbon footprint. Additionally, the bags are collapsible, reducing storage space requirements and optimizing transportation efficiency.

6.Versatile and Cost-Effective:

BIB filling machines accommodate a wide range of liquid products, making them versatile for various industries. Whether it's wine, juice, water, or even industrial liquids, these machines can handle diverse viscosities and volumes. Their adaptability and flexibility make them a cost-effective packaging solution for businesses of all sizes.

7.Branding and Marketing Opportunities:

BIB packaging offers ample space for branding and marketing messages. The large surface area of the cardboard box allows businesses to showcase their logo, product information, and engaging graphics. This creates opportunities to attract consumer attention, reinforce brand recognition, and communicate key messages effectively.

What types of BIB filling machine?

There are several types of Bag-in-Box (BIB) filling machines available, each designed to cater to specific needs and production requirements. Here are some common types of BIB filling machines:

1.Manual BIB Filling Machines: These machines are operated manually and are suitable for small-scale or low-volume production. They often have a lever or pedal mechanism that allows the operator to control the filling process. Manual BIB filling machines are cost-effective and suitable for businesses with limited production needs.

2.Semi-Automatic BIB Filling Machines: Semi-automatic machines offer a combination of manual and automated functions. They typically require some operator intervention but also incorporate automation for filling, sealing, and other processes. These machines are suitable for medium-sized businesses with moderate production volumes.

3.Aseptic BIB Filling Machines: Aseptic BIB filling machines are specialized equipment designed for aseptic or sterile filling of BIB bags. They incorporate features such as sterilization systems, controlled environments, and sterile product supply to ensure the preservation of product quality and prevent contamination. Aseptic BIB filling machines are commonly used in industries that require long shelf life and strict hygiene standards.

BIB bag size and loading weight

BIB bags come in various sizes and weight capacities to accommodate different liquid products and consumer needs. The most common BIB bag sizes range from 1 liter to 20 liters, although larger sizes may also be available for industrial or commercial applications. The weight capacity of a BIB bag depends on its size and the specific product it is designed to hold.

Here are some typical BIB bag sizes and weight capacities:

1 liter BIB bag: This size is commonly used for single-serving portions or sample packs. The weight capacity for a 1-liter BIB bag can range from 0.8 kg to 1.2 kg, depending on the density of the liquid.

3-liter BIB bag: This size is popular for household use, especially for beverages like wine or juice. The weight capacity for a 3-liter BIB bag typically ranges from 2.5 kg to 3.5 kg.

5-liter BIB bag: This size is commonly used for household and commercial applications. It is suitable for products with higher consumption rates or for events and gatherings. The weight capacity for a 5-liter BIB bag can range from 4 kg to 5.5 kg.

10-liter BIB bag: This size is often used in commercial settings such as restaurants, bars, and catering services. It offers a larger volume for high-demand situations. The weight capacity for a 10-liter BIB bag typically ranges from 8 kg to 11 kg.

20-liter BIB bag: This size is commonly used in industrial settings or for bulk packaging of liquids. It is suitable for large-scale operations and offers significant cost savings. The weight capacity for a 20-liter BIB bag can range from 15 kg to 22 kg.

It's important to note that the weight capacity mentioned above is an approximate range and can vary based on the specific bag manufacturer, material used, and the density of the liquid being filled.

When selecting a BIB bag size and weight capacity, it is crucial to consider factors such as the intended application, consumption rate, storage space, and logistical requirements to ensure optimal packaging and customer satisfaction.

Conclusion:

Bag-in-Box filling machines have transformed the liquid packaging industry by providing a streamlined, efficient, and sustainable solution. Their precise filling capabilities, extended shelf life, convenient dispensing, and reduced packaging waste make them an attractive choice for businesses. Embracing BIB filling machines enables companies to optimize their packaging operations, enhance product quality, and meet the demands of today's environmentally conscious consumers. By investing in this advanced technology, businesses can unlock new opportunities for growth and success in the competitive marketplace.

Contact: 101Packing

Phone: +86 198 7511 8892

E-mail: info@101packing.com

Add: 5th Floor, Outside Building, Shangxue Tech Park, Jihua Road, Longgang District, Shenzhen,Guangdong,China