Model:PK-C158

Production Capacity:10000-30000 (Pills/Hour )

Motor power:0.55KW

Power supply:220V/50HZ

The max forming area and depth:134mm×70mm×14mm

PVC:Length: 65-70mm, thickness: 0.025mm

PTP:Length: 65-70mm, thickness: 0.02mm

PVC hard piece: width: 65-90 mm, thickness: 0.25-0.30 mm

Bore diameter of roll shaft: 60-70 mm

PTP aluminum foil: width: 65-70 mm, thickness: 0.02-0.025 mm

Bore diameter of roll shaft: 60-70 mm

Inside diameter of wrapper roll:70-76mm

Air Compressed:0.4Mpa

Packing width:(Max width) 160 mm

Weight: 420kg

Overall Dimension:

(L×W×H)1260×850×1700mm (Vibration type)

(L×W×H)1280×850×1350mm (Rotary type)

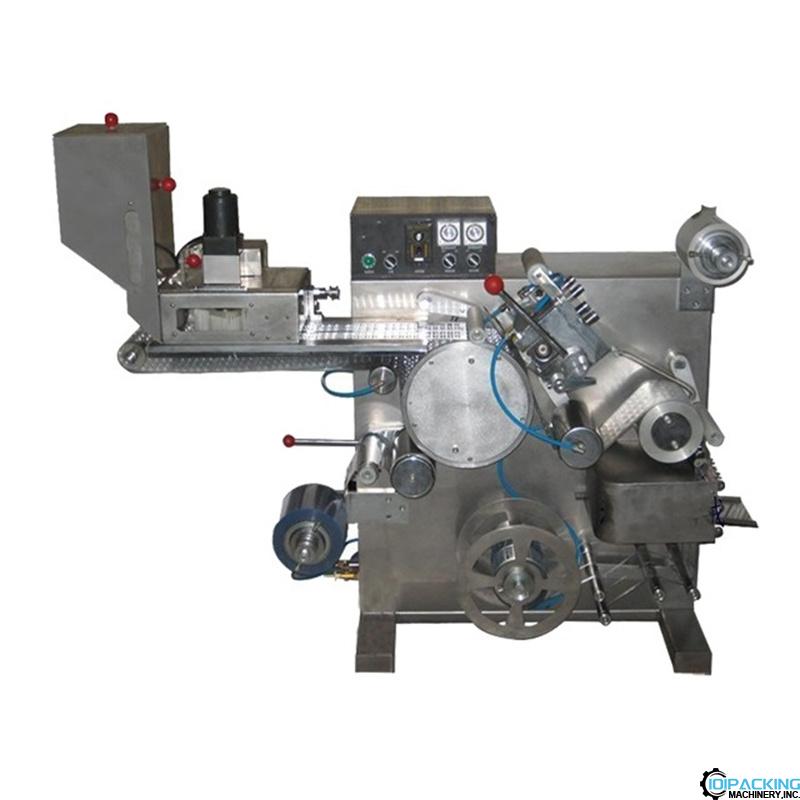

Automatic pharm tablet capsule blister producing packing machine

Model:PK-C158

Production Capacity:10000-30000 (Pills/Hour )

Motor power:0.55KW

Power supply:220V/50HZ

The max forming area and depth:134mm×70mm×14mm

PVC:Length: 65-70mm, thickness: 0.025mm

PTP:Length: 65-70mm, thickness: 0.02mm

PVC hard piece: width: 65-90 mm, thickness: 0.25-0.30 mm

Bore diameter of roll shaft: 60-70 mm

PTP aluminum foil: width: 65-70 mm, thickness: 0.02-0.025 mm

Bore diameter of roll shaft: 60-70 mm

Inside diameter of wrapper roll:70-76mm

Air Compressed:0.4Mpa

Packing width:(Max width) 160 mm

Weight:420kg

Overall Dimension:

(L×W×H)1260×850×1700mm (Vibration type)

(L×W×H)1280×850×1350mm (Rotary type)

It is suitable for packing tablets, capsules and mini electronic components and solid articles in the medical industry and can reach good tightness performance and damp proof effect .

The machine can continually and automatically complete the packing proceedings ,is blister cap form-taking .medicine-feeding ,hot-sealing ,printing lot no ,and cutting into format .It has advantages as compact structure ,full function ,gear wheel working ,accurate aynchr-onization ,stable cooperation ,easy to replace the mould ,low cost and needn’t to equip auxiliary unit .

Contact: 101Packing

Phone: +86 198 7511 8892

E-mail: info@101packing.com

Add: 5th Floor, Outside Building, Shangxue Tech Park, Jihua Road, Longgang District, Shenzhen,Guangdong,China