Model:PK-5HEF240

Filling needles:5 heads

Max forming depth:12mm

Cutting frequency:1-25?Times

Film materials:PVC/PE etc(0.2-0.4)×240mm

Capacity:6000 bottles per hour

Filling range:1-50ml

Installed power:6.5kw

Voltage:220v or 380v/50Hz (up to client's request)

Weight(kg):1200kg

Outer Size L×W×H(mm):3200×850×1400(mm)

Automatic liquid disposal syringe tray 4 nozzles filling producing equipment

Model:PK-5HEF240

Filling needles:5 heads

Max forming depth:12mm

Cutting frequency:1-25?Times

Film materials:PVC/PE etc(0.2-0.4)×240mm

Capacity:6000 bottles per hour

Filling range:1-50ml

Installed power:6.5kw

Voltage:220v or 380v/50Hz (up to client's request)

Weight(kg):1200kg

Outer Size L×W×H(mm):3200×850×1400(mm)

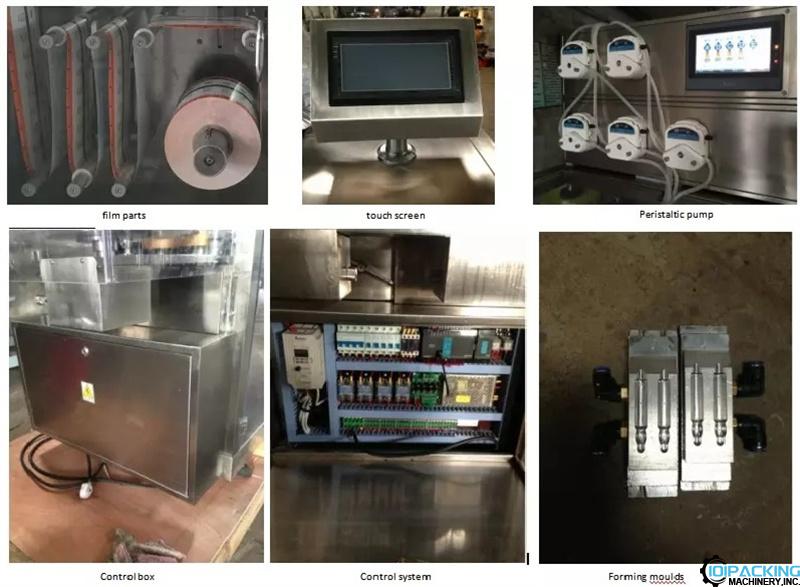

Eye drop plastic ampoule tray film forming filling sealing cutting machine is suitable for the unit close of medicine, drinks, dairy products, health products, food, cosmetics, perfumes, agricultural medicine, fruit purees, etc. Features A. HC high speed and high precision high-end motion controller, stepless frequency control of motor speed control, servo motor control tensile membrane devices. B. The man-machine interface, device, operation is simple. C. Automatic discharge volume, a roll of film cutting, can be folded in half, there are positive and negative photoelectric pattern of version of the function. Products elegant, meet high standards of packaging requirements. D. Adopting electronic peristaltic pump device, and mechanical pump piston pump control. Adjustment is convenient. Filling accuracy is correct. E. Filling does not drip, no bubble, no overflow. F. Parts in contact with the medicine with high quality stainless steel 316L, machinery casings are all SUS 304 stainless steel, In line with the GMP standard. G. Saving films H.Machines can fission, convenient transportation and easy into the workshop.

Contact: 101Packing

Phone: +86 198 7511 8892

E-mail: info@101packing.com

Add: 5th Floor, Outside Building, Shangxue Tech Park, Jihua Road, Longgang District, Shenzhen,Guangdong,China