Model:PK-SC60FM

All the machine will be Automatic, PLC control.

Control board: touching screen.

Defective Rate:>99.5%.(without desiccant or cardboard).

Desiccant dosage: ±2%.

Machine Capacity:60 pcs/Min

Power:2.5KW

Air consumption: 0.5 Mpa/Hour

Machine Rate Current: 220V,single phase,50 HZ

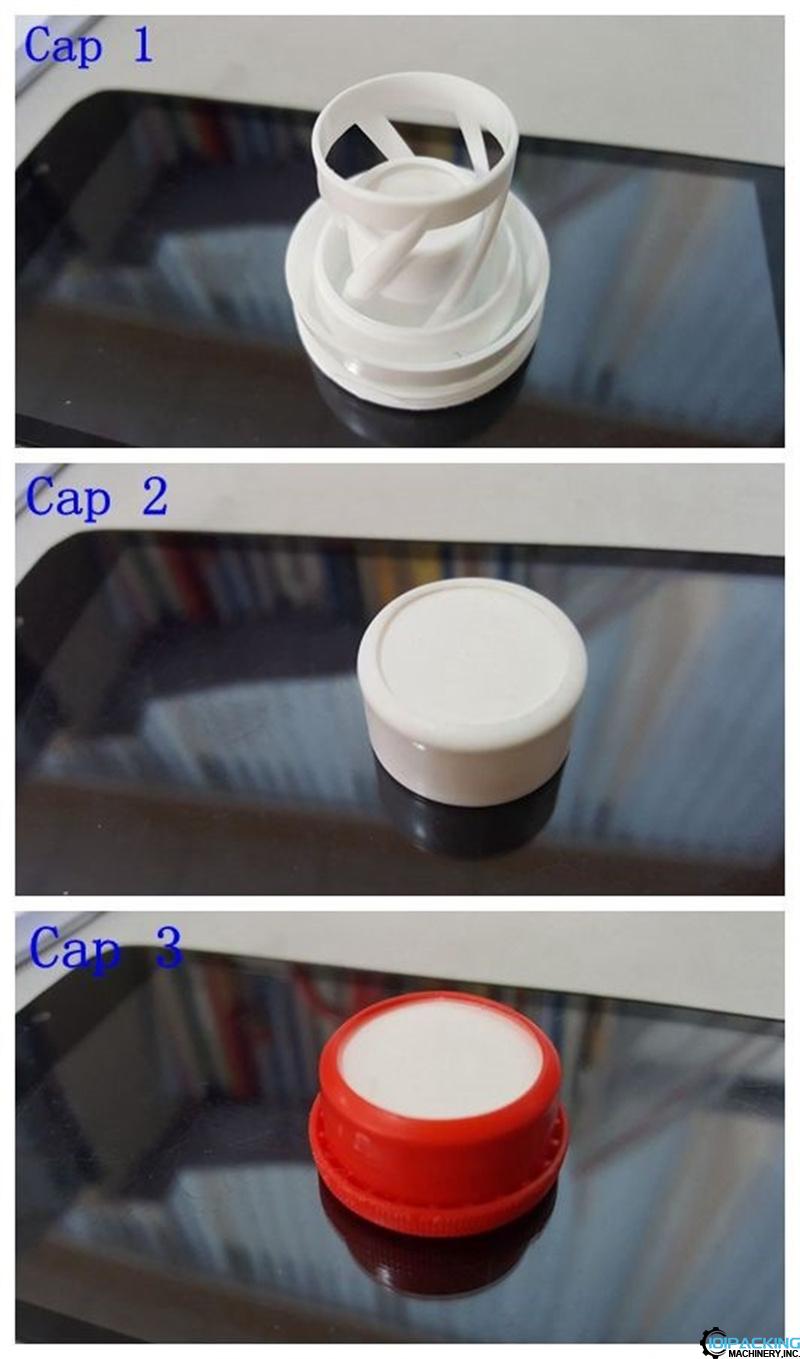

Automatic desiccant tube cap spring cloure lid assembly machine

Model:PK-SC60FM

All the machine will be Automatic, PLC control.

Control board: touching screen.

Defective Rate:>99.5%.(without desiccant or cardboard).

Desiccant dosage: ±2%.

Machine Capacity:60 pcs/Min

Power:2.5KW

Air consumption: 0.5 Mpa/Hour

Machine Rate Current: 220V,single phase,50 HZ

With counter installed for counting.(outlet Shift Device is optional)

Cap Detective sensor: Once the sensor detect no caps in one head,the machine will stop ,the worker can manual add one cap under the sensor to move on with production.

Desiccant detective sensor &Liner detective sensor: these 2 sensors will detect the caps without desiccant filling and without cardboard liner inserting,and give order to the rejection unit to reject these caps automatic,the caps will not stop for replacing.

Desiccant will be feeding by manual to the desiccant container. And measurement automatic.

Contact: 101Packing

Phone: +86 198 7511 8892

E-mail: info@101packing.com

Add: 5th Floor, Outside Building, Shangxue Tech Park, Jihua Road, Longgang District, Shenzhen,Guangdong,China