Model:PK-T40A

Voltage;110/220V 50/60Hz

Production capacity:10-60 pcs/min

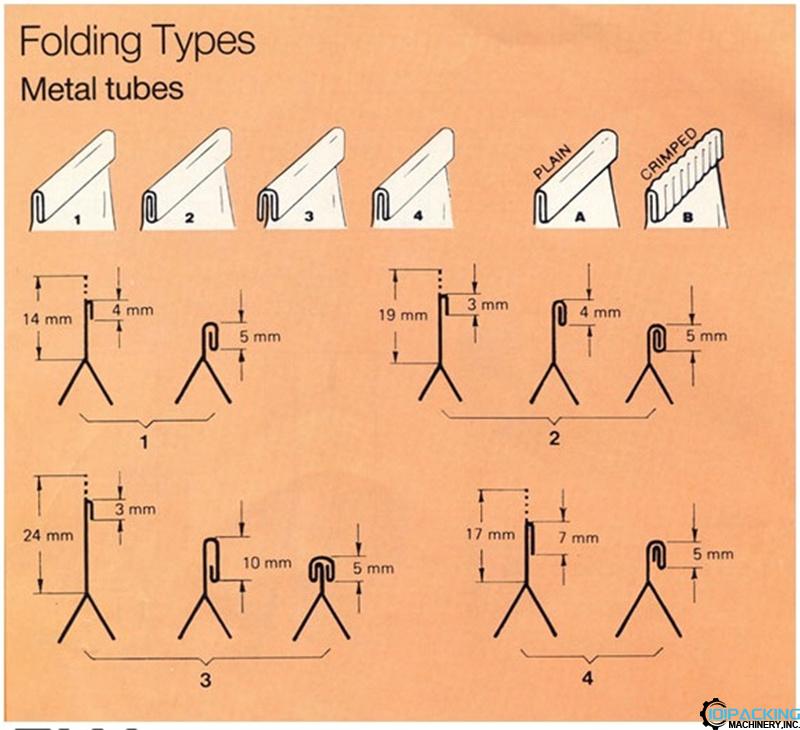

Folding type:4 folds( can be customized 3 folds)

Filling volume:5-200 ml ( 5-75ml/30-150ml/150-250ml,other filling range can be customized)

Filling accuracy:± 1%

Rejection rate:< 1%

Hopper volume:40 L ( can be customized)

Motor power:1.1 kW

Air consumption:0.6 m3/min

Compressed air:0.4 MPa

Dimension:1850*950*1980mm

Net weight:750Kg

Automatic aluminum soft tube metal tube feeding filling folding machine

Model:PK-T40A

Voltage;110/220V 50/60Hz

Production capacity:10-60 pcs/min

Folding type:4 folds( can be customized 3 folds)

Filling volume:5-200 ml ( 5-75ml/30-150ml/150-250ml,other filling range can be customized)

Filling accuracy:± 1%

Rejection rate:< 1%

Hopper volume:40 L ( can be customized)

Motor power:1.1 kW

Air consumption:0.6 m3/min

Compressed air:0.4 MPa

Dimension:1850*950*1980mm

Net weight:750Kg

Product Application:paste, adhesives, skin cream, hair dye, shoe polish, toothpaste, shampoo

Automatic aluminum tube hose inserting rotary cream paste oil liquid filling folding sealing machine with empty tube loading feeding tank is specially designed for clients to manufacturer instant glue, Chemical or medicine. A dual four-fold sealing is reached after each turn of a station .It use automatic folding. Because it is safe and airtight, so we can ensure the excellent quality of the products .This machine are take unlimited adjustment speed and photoelectric control. No tube no filling. As for different metal pipe, we can do it just through put on the mold with different diameters.

Tube material: aluminum soft tube

Filling material: all kind of cream, latex, lotion, oil and water etc.

Machine working process:

Tube feeder(container for hoses) → automatic tube feeding → positioning → inside of hoses' cleaning(can be chose to use or not) → filling → flattening → crimping 90° → flattening → crimping 90° → flattening → crimping -90° → flattening → printing→ finished product discharging

Contact: 101Packing

Phone: +86 198 7511 8892

E-mail: info@101packing.com

Add: 5th Floor, Outside Building, Shangxue Tech Park, Jihua Road, Longgang District, Shenzhen,Guangdong,China